The in-mold coating course of eliminates the necessity for drying furnaces, lowering carbon dioxide emissions by roughly 60%

Toyoda Gosei and Kansai Paint have developed an in-mold coating know-how that enables massive plastic automotive components to be shaped and painted inside moulds. The know-how represents the primary time in Japan that in-mold coating has change into relevant to mass manufacturing of huge exterior components.

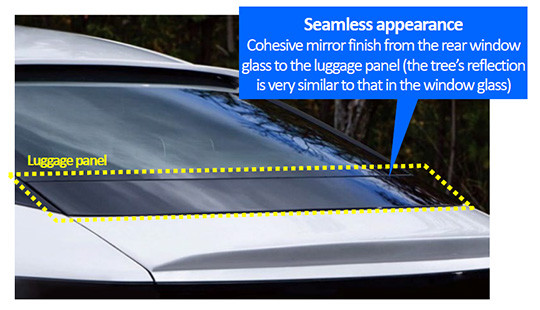

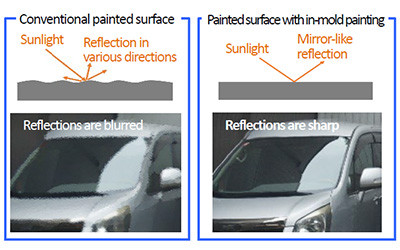

The know-how makes use of Toyoda Gosei’s mould know-how for giant components and paint materials design developed by collaboration between the 2 corporations. The method achieves a seamless look with excessive smoothness of the painted floor, enabling new moulding designs for exterior components.

The know-how eliminates the necessity for a drying furnace, lowering carbon dioxide emissions throughout manufacturing by roughly 60%. Sturdiness is improved by the usage of urethane paint, making abrasions throughout washing much less seen.

Massive painted merchandise utilizing the know-how are scheduled for market launch in spring 2026. Toyoda Gosei plans to implement the know-how at its worldwide manufacturing websites as a part of its ornamental applied sciences providing.

The 2 corporations mentioned they are going to proceed collaborating to use the know-how to a wider vary of merchandise, contributing to automobile design whereas lowering carbon dioxide emissions.

The upper stage of smoothness with in-mold coating provides sharper reflections within the product floor

SOURCE: Toyoda Gosei