Arch Techniques’ CTO weighs in on how knowledge analytics are serving to to form the manufacturing facility of the long run. By Megan Lampinen

The digital revolution is reshaping not solely automobiles but in addition the factories that make them. As buyer necessities evolve and environmental requirements tighten, automakers are underneath stress to optimise all elements of producing effectivity. Whether or not it’s 5G sending real-time knowledge insights from the manufacturing facility ground or AI selecting up on anomalies earlier than catastrophe strikes, automotive producers are remodeling their crops into good manufacturing hubs.

US-based Arch Techniques is simply one of many firms shaping the manufacturing facility of the long run. Its mission: to assist producers unlock the total worth of their manufacturing facility knowledge with out forcing disruptive overhauls. “Such disruption is not mandatory, though many producers don’t realise it but,” says Tim Burke, Arch Co-Founder and Chief Know-how Officer.

Burke leads a staff of skilled knowledge and manufacturing consultants constructing next-generation merchandise that deeply perceive manufacturing processes and floor clever actions to enhance them routinely. He tells Automotive World that this type of functionality is ushering in a brand new paradigm wherein knowledge turns into the widespread language of producing.

What are among the ache factors on the automotive manufacturing facility ground at the moment?

Automotive factories are a storm of complexity. Mannequin variations, electrical car modifications, and quicker product lifecycles are making manufacturing more and more dynamic, which suggests it’s more durable than ever to handle. On prime of that, no two crops are the identical, even throughout the identical firm. It’s a sea of machines from totally different distributors all with totally different vintages, capabilities, and ranges of connectivity. That range is what permits the fashionable marvel of producing to work. It’s additionally what creates an excessive problem in standardisation and scaling greatest practices.

The place do you see alternative to sort out a few of these points?

One of many greatest alternatives lies in connecting the information that already exists and leveraging new knowledge practices and AI to do that in a a lot quicker and extra comprehensible means. Scaling experience turns into a lot simpler with these instruments, driving us to a practical way forward for superior detection and proposals from new, trendy applied sciences. This enables automotive producers, which haven’t any scarcity of sensors, logs and high quality metrics, to show that data into particular beneficial actions at scale that drive uptime, yield, and even sustainability.

What applied sciences and traits maintain the most important potential to rework automotive manufacturing?

We’re working at a time when AI and connectivity are firmly in play. The instruments to perform which might be available. What was solely completed in-house has transferred to a market that provides it at each decrease price and quicker time to worth. The following leap is integration and orchestration: linking all of the good techniques into one coherent ecosystem. Digital twins, edge analytics and adaptive management techniques have matured in a short time and proceed to take action, however their full worth actually is available in after they can speak to one another and create suggestions loops throughout the enterprise. That is the following frontier that’s getting all operational leaders excited and pushing them via what was the drudgery of getting there.

One other main shift underway is the transfer from optimising particular person property to optimising complete techniques and organisations. Now that end-to-end feels attainable, leaders are actively pursuing initiatives that transfer from native enhancements to world coordination. The mixture of standardised knowledge fashions, real-time analytics, and AI-driven suggestions will make that attainable at scale.

The place does Arch Techniques come into the image?

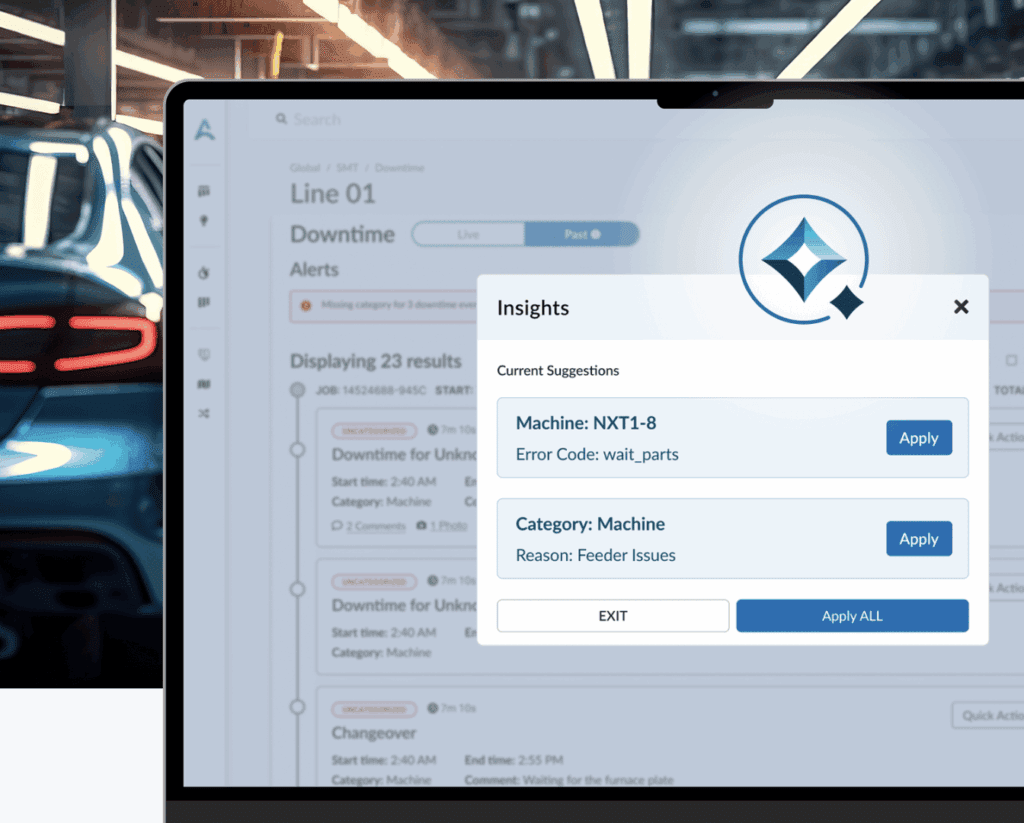

We deal with connecting machines and techniques throughout numerous tools and websites, enabling knowledge to move securely and contextually from edge to cloud. Our platform then makes use of expert-guided and AI-driven analytics so the ‘so-what’ behind the information might be realised: uncovering inefficiencies, predicting points earlier than they ever happen, and offering actionable steerage that drives measurable enchancment. In brief, Arch helps producers transfer from visibility to motion, turning their current knowledge into an operational benefit.

What improvements inside Arch would you regard as notably impactful for the manufacturing sector?

A core innovation from Arch is our real-time anomaly detection and root trigger suggestion engine. It identifies delicate shifts in course of behaviour that precede downtime or high quality points, giving groups time to behave earlier than they escalate and have damaging impacts on productiveness.

One other is our fast onboarding and edge connectivity framework. This enables even the extra legacy-type tools to take part actively in trendy knowledge ecosystems. That accelerates deployment reduces integration friction, and helps clients scale out digital transformation initiatives plant-by-plant in a short time. In actual fact, this can be a hallmark of our work; we’ve had clients publicly acknowledge our rollout and implementation time because the quickest initiative in firm historical past. It’s an space the place we actually excel.

As factories develop smarter and extra environment friendly, what does this imply for the workforce?

Good factories elevate the position of individuals. It’s that easy. As techniques grow to be extra able to analysing knowledge and flagging points, operators and engineers have to spend much less time trying to find and documenting issues and extra time fixing them and upskilling the following technology of employees. That is the place AI works phenomenally nicely in service of individuals.

This shift is essentially altering what experience appears to be like like. Probably the most priceless abilities are transferring towards interpretation, coordination and enchancment, utilizing insights from related techniques to drive higher outcomes. The hot button is to design expertise that matches manufacturing workflows and empowers the individuals inside them. When that is finished proper, AI and automation amplify human judgment, slightly than substitute it, and considerably decrease the burden to leverage that experience.

Is lights-out manufacturing a sensible goal?

Lights-out manufacturing has many meanings. Some have interpreted it to imply a very ‘darkish manufacturing facility’, the place the whole lot is automated 24/7, no human on web site, not even lights, heating, air con, and many others. It makes for a pleasant headline, however it’s a slender actuality. It’s very uncommon at the moment and never a sensible goal for many producers. Neither is it their near-term aim. Why? As a result of it’s sensible for under extremely secure and repeatable processes with little variation. That’s not the state of most factories at the moment.

What’s much more achievable, and much more priceless, is one thing like ‘lighthouse manufacturing’. Slightly than the aim of getting each manufacturing facility be lights out, the aim is for each manufacturing facility to be a lighthouse, with world-class operations that run longer, smarter, and with fewer disruptions as a result of knowledge, automation, and human experience are tightly coupled. Complete autonomy isn’t the aim. Steady enchancment and constructing larger resilience into the system are.

What does the manufacturing facility of the long run seem like to you?

The manufacturing facility of the long run is a related, adaptive, and self-improving setting. It’s a spot the place each machine, course of, and individual contributes to a steady studying loop. It would combine real-time knowledge throughout machines, suppliers and clients right into a single, dynamic view of operations, permitting leaders to simulate, predict, and optimise in actual time. Factories will not simply produce merchandise; the manufacturing facility itself can be handled extra like a product and evolve alongside them.

Probably the most superior producers will discover that stability between world consistency and native flexibility. There’s a variety of innovation even in that seemingly diminished house. Making knowledge the widespread language of producing, the place each manufacturing facility learns from each different, is what Arch helps to allow. Excellence anyplace can grow to be excellence in all places.