Aluminium gives a number of advantages in the case of producing protected, light-weight automobiles. By Megan Lampinen

Metal has served because the spine of auto manufacturing for greater than a century, however the shift to new mobility is disrupting the fabric combine. Over the previous few years, aluminium has emerged because the quickest rising automotive materials. Its light-weight properties, sturdiness, security and sustainability benefits have made it a key device within the business’s adaption to new mobility calls for.

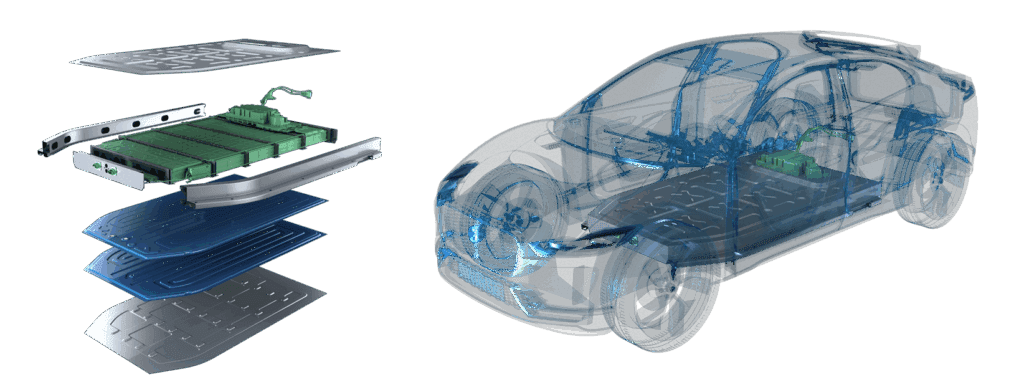

What was as soon as reserved for luxurious and high-performance automobiles is now broadly used throughout all automobile segments, from compact vehicles and SUVs to sports activities vehicles and pick-ups. It’s discovering its approach into key purposes resembling physique panels, bonnets/hoods, doorways, physique in white constructions and electrical automobile (EV) battery enclosures.

Not solely is aluminium now utilized in a greater diversity of automobiles and purposes, however the quantity used per automobile has additionally elevated. A 2022 examine commissioned by European Aluminium and carried out by Ducker Carlisle discovered that the common quantity of aluminium utilized in European vehicles has elevated by 18% from 174kg in 2019 to 205kg in 2022. This development is about to proceed, with the common aluminium content material projected to succeed in 237kg per automobile by 2026 and 256kg by 2030.

Market drivers

There are a number of elements driving demand. To begin with, aluminium gives a notable automobile weight discount in comparison with conventional metal. Based on Alumobility, it has one-third the density of metal. When evaluating two equivalent automobiles (one metal and one aluminium), each with equal stiffness and load-carrying capability, the aluminium automobile physique might be as much as 45% lighter.

“Higher use of aluminium aligns with the rising emphasis on lightweighting, which has gained prominence as automakers look to stability price and sustainability with out compromising structural integrity,” says Michael Hahne, Vice President Industrial for Europe at aluminium provider Novelis. “Changing 400kg of metal with 240kg of aluminium can dramatically cut back weight and materials utilization.” This has a direct influence on gasoline effectivity or EV vary. “Its weight benefit is a game-changer for EVs, the place battery vary is a serious consideration,” he tells Automotive World. The business’s shift towards electrification is growing demand for lighter supplies usually to fight the extra weight of the battery.

It additionally contributes to secondary financial savings in areas like braking and suspension techniques, as lighter automobiles require smaller braking and suspension parts. Within the earlier instance, the place 400kg of metal is changed with 240kg of aluminium, the automobile can even see one other 40-60kg weight saving from different areas.

Aluminium performs effectively on the protection entrance, because it absorbs extra vitality than metal per kilogram, that means occupants are higher shielded from intrusion into the protection cell. Because the automobile carries much less mass right into a collision, aluminium our bodies will be much less damaging in incidents involving different automobiles, cycles, and pedestrians. “Aluminium continues to be a useful materials for automobile security,” notes Hahne. “Crash assessments verify automobiles made lighter with aluminium our bodies earned excellent five-star crash scores.”

Aluminium additionally performs a key position in enabling a round economic system. Closed-loop recycling techniques enable OEM manufacturing scrap, in addition to scrap from end-of-life automobiles, to be repurposed in a round method, decreasing carbon emissions throughout the manufacturing course of in comparison with major aluminium manufacturing. Novelis just lately developed the world’s first automotive aluminium coil made totally from 100% recycled end-of-life automobile scrap. This materials, designed to satisfy the business’s robust requirements for automobile physique outer pores and skin purposes, marks a notable milestone in assist of automotive circularity.

“Aluminium stands out for being infinitely recyclable, sustaining its materials properties by numerous life cycles,” provides Hahne. Recycling aluminium saves as much as 90% of CO2 emissions in comparison with major aluminium manufacturing, making it a cornerstone materials for wider carbon discount methods.

The place subsequent?

Regardless of the quite a few benefits, aluminium usually carries the next price than metal. It additionally entails extra energy-intensive manufacturing and specialised manufacturing necessities. However R&D advances from gamers like Novelis promise additional enhancements each throughout the materials itself in addition to manufacturing methods. For example, the corporate has been engaged on aluminium roll forming, a course of that exactly shapes steel into advanced automotive constructions. This could cut back part prices and enhance structural efficiency and security, significantly in EVs the place battery safety is important. Novelis has additionally been working with Jaguar Land Rover on a brand new aluminium pores and skin alloy, which options as much as 85% recycled content material and is 95% extra vitality environment friendly to supply.

Whereas aluminium use is rising, metal isn’t standing nonetheless. Developments round superior excessive energy metal have produced important weight reductions, with the newest grades claiming to chop automobile weight by 35-40% in comparison with conventional metal. The argument from aluminium proponents like Novelis is that its distinctive properties deliver important benefits that transcend the drawbacks. “Shifting the dialog from upfront bills to the long-term worth and efficiency good points supplied by aluminium is important to unlocking its full potential in revolutionising the auto business,” emphasises Hahne.