The shift to centralised programs is anticipated to pressure the reliability and security of auto E/E architectures

The automotive trade is present process a profound transformation, pushed by the rise of software-defined autos (SDVs). These autos promise to redefine mobility by shifting worth creation from mechanical efficiency to digital buyer experiences. Nonetheless, realising this imaginative and prescient requires a elementary rethinking of the car’s electrical and digital (E/E) structure.

To help the calls for of contemporary mobility reminiscent of autonomous driving, over-the-air updates, and real-time knowledge processing automakers are transitioning from conventional, decentralised programs to centralised and zonal architectures. As an alternative of counting on tons of of digital management models (ECUs) managing particular person features, the centralised structure consolidates computing energy into fewer, strategically positioned clusters. This modular method enhances scalability, reduces complexity, and allows sooner innovation cycles.

But, as software program takes centre stage, the reliability of the underlying {hardware} turns into much more vital. Excessive-performance chips and delicate digital elements should function flawlessly underneath harsh automotive circumstances. Any compromise in bodily integrity might result in system failures with critical security implications.

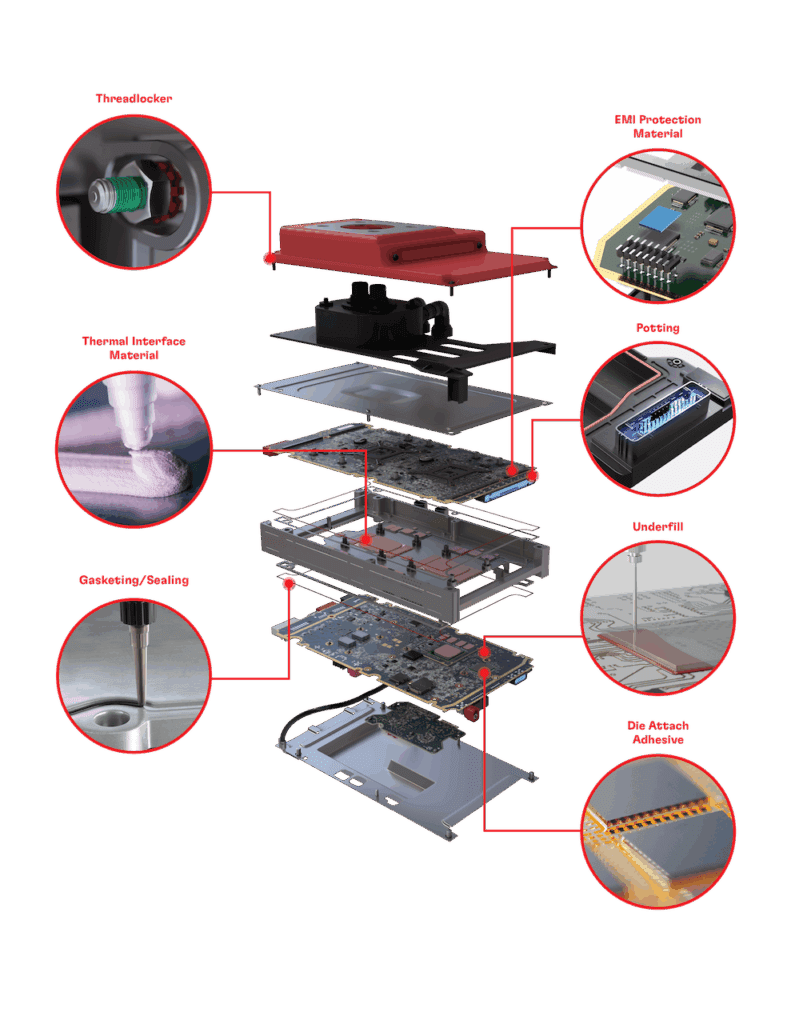

That is the place know-how options from Henkel play a vital function. With deep experience in adhesives and sealants, it’s serving to to guard next-generation car electronics from thermal, mechanical, and environmental stress. As autos change into extra linked and software-driven, the corporate’s options guarantee the sturdiness and security of the {hardware} powering them.

Thermal and EMI dangers in high-performance automotive electronics

Most OEMs and Tier 1 suppliers face comparable challenges in transitioning to centralised architectures, and these should be addressed early within the SDV design course of. One main problem is warmth technology: integrating with a number of features into high-performance chips will increase real-time knowledge processing, which in flip results in increased warmth output inside densely packed elements.

Though the dangers are nicely understood, every OEM is pursuing a special design technique

The chance of programs present process extreme thermal biking, vibration, and publicity to harsh environmental circumstances poses a critical menace to total reliability, particularly since high-performance chips are sometimes used to deal with security vital features Examples embrace sensor {hardware} and acceleration/braking programs in robotaxis, the place failure might lead to expensive penalties.

Furthermore, as automakers try to optimise house and weight, digital elements are being built-in into smaller packages that share energy provides and wiring. This will increase the chance of electromagnetic interference (EMI), the place undesirable electrical noise disrupts a tool’s regular operation, doubtlessly resulting in diminished efficiency, malfunction, or failure.

Though the dangers are nicely understood, every OEM is pursuing a special design technique, making it important for Tier 1 suppliers to construct flexibility into their merchandise. The result’s a extremely complicated transition in E/E structure. Pace has change into the brand new norm, and automotive corporations are underneath stress to speed up time to market. They need to increase processing capabilities whereas sustaining security and reliability and managing rising system complexity.

Bringing reliability and safety via adhesive options

Henkel leverages its intensive technical experience and complete portfolio of superior supplies and engineering providers to help the trade’s calls for wholistically .By participating early within the design section, it ensures the correct answer for each structure and utility, addressing challenges proactively.

- Thermal administration: Henkel affords full-stack options from chip to cooling plate, together with hole fillers, gels, greases, section change supplies, thermal adhesives, and insulating pads—guaranteeing environment friendly warmth dissipation and system stability.

- Reliability: Adhesives and safety supplies like underfills to guard chips, potting and encapsulation supplies; gasketing and sealants for delicate electronics safety; and conformal coatings are designed to face up to harsh circumstances and help high-throughput manufacturing.

- EMI shielding: To boost electromagnetic compatibility efficiency, Henkel supplies EMI absorbers, shielding supplies reminiscent of movie and gasketing, grounding options, and multifunctional merchandise that mix thermal and EMI safety.

- Reworkability and circularity: Debonding-on-Demand know-how allows secure, non-destructive disassembly of high-value elements, supporting restore, reuse, and sustainability objectives.

- Time to market: With a globally out there and domestically manufactured portfolio, Henkel ensures fast product accessibility. Its simulation providers speed up element design and validation, serving to clients shorten improvement cycles and convey improvements to market sooner.

Henkel delivers confirmed options for superior automotive electronics

One in every of Henkel’s clients encountered important challenges in managing warmth dissipation from a complicated system on chip inside its ADAS Area Management module utilizing conventional thermal interface materials with low thermal conductivity.

Leveraging its long-standing experience in automotive electronics and deep understanding for c, and by collaborating carefully with the shopper from the earliest design phases, Henkel efficiently developed a high-thermal conductivity materials (TC> 10W/mk) that delivers distinctive thermal efficiency, extremely strong shelling out behaviour, minimal oil bleeding and uncompromising reliability, even underneath probably the most demanding working circumstances.

As well as, as a key companion all through the idea section, Henkel proactively addressed necessities extending past thermal administration, together with element safety (underfill, gasketing, and potting) and EMI shielding. By offering a portfolio of absolutely appropriate merchandise, it ensured that each one supplies built-in seamlessly inside the element structure.

Collectively, these capabilities place Henkel as a strategic companion in enabling secure, dependable, and environment friendly E/E structure transitions for next-generation autos.

It is a sponsored article produced in collaboration with Henkel