Sponsored by TE Connectivity.

Driving the Way forward for Mobility.

The automotive business is present process a major evolution, pushed by altering client calls for and shifting expectations for personalization, connectivity, security, electrification, and enhanced options and performance. Underpinning this transformation is the design evolution of next-generation electrical/digital (E/E) automobile architectures that are unlocking a brand new period of smarter, safer and extra handy mobility together with extra environment friendly manufacturing processes.

To deal with growing expectations for practical sophistication and effectivity, next-gen E/E automobile architectures leverage centralized management items and zonal designs. These improvements allow practical software-driven consolidation with over-the-air (OTA) updates, optimized information and energy distribution, decreased wiring harness complexity and weight, in addition to elevated design flexibility and scalability for future innovation.

Beneath, we discover the pivotal traits and challenges – from autonomous driving and elevated connectivity to electrification and the rise of shared mobility – which can be shaping next-generation automobile architectures, and the important function connectivity performs in enabling this transformation.

Picture 1: At this time’s automobile patrons prioritize PACES – personalization, automated and autonomous, connectivity, electrification and sustainability options – demanding immersive, future-ready mobility experiences over conventional possession fashions.

The Advantages of Zonal Architectures: Effectivity Meets Innovation

Conventional E/E architectures can not hold tempo with the complicated calls for of recent autos. They depend on complicated and vehicle-spanning wire harnesses, which regularly end in inefficiencies and elevated weight. Subsequent-gen architectures, characterised by zonal designs and centralized management, are setting a brand new normal.

Picture 2: Automobile Structure Transformation

Zonal architectures characteristic centralized, extra highly effective management items which can be organized into distinct zones, offering extra trendy computing buildings that allow server-based software program processes. This strategy not solely simplifies and reorganizes wire harnesses but in addition helps extra environment friendly, higher-speed transmission and real-time processing of extra sensor and environmental information. The target is fewer nodes/ECUs however considerably extra connection alternatives (ports) per node — linked collectively by a high-speed information spine. This strategy not solely streamlines the wiring harness, lowering its weight and complexity, but in addition paves the best way for extra scalable and versatile automobile designs and practical deployment. Consider zonal architectures as cities with well-organized neighborhoods, every with its personal utilities and providers, all related by a high-speed freeway. The important thing advantages embrace the next:

- Simplified wiring: Zonal architectures have important implications for automobile design and manufacturing. As zone-based set up approaches change unwieldy, vehicle-spanning harnesses, it turns into potential to make use of lighter cabling programs. This enhances electrical effectivity, reduces weight and simplifies harness set up and, resulting from higher partitioning, makes automated harness manufacturing an choice.

- Scalable design: Bodily restructuring additionally makes it potential to pre-equip a automobile for future upgrades. By over-the-air (OTA) updates, software-defined autos (SDVs) can proceed so as to add — as paid subscription providers — worth and performance lengthy after leaving the manufacturing line, with no need to have any {hardware} put in or modified. Some examples of upgrades already being supplied by choose OEMs is the momentary activation of extra efficiency, extra battery vary, or larger ranges of autonomous driving.

- Enhanced effectivity: Centralized management items and higher partitioning permit for improved vitality administration and facilitate the automated manufacturing of harnesses.

What Do Subsequent-Gen E/E Architectures Imply for the Way forward for Mobility?

These architectures empower automakers to create autos which can be versatile, future-proof, and cost-effective. Subsequent-gen E/E architectures allow the combination of a rising variety of modern capabilities for design, efficiency, and performance — from autonomous driving and superior driver-assistance programs (ADAS) to enhanced infotainment and battery administration programs. Excessive-speed information networks and modular connectivity options facilitate the seamless communication and management of those programs, making certain environment friendly vitality administration and an improved driving expertise. As well as, as energy calls for proceed to rise, transitioning from conventional 12V programs to 48V architectures helps decrease present ranges, lower warmth loss in wiring, and improve total effectivity. The shift to 48V permits higher thermal administration and helps scalable, high-power computing platforms whereas aligning with the evolving wants of software-defined automobile architectures.

Connectivity: The Spine of Smarter Automobiles

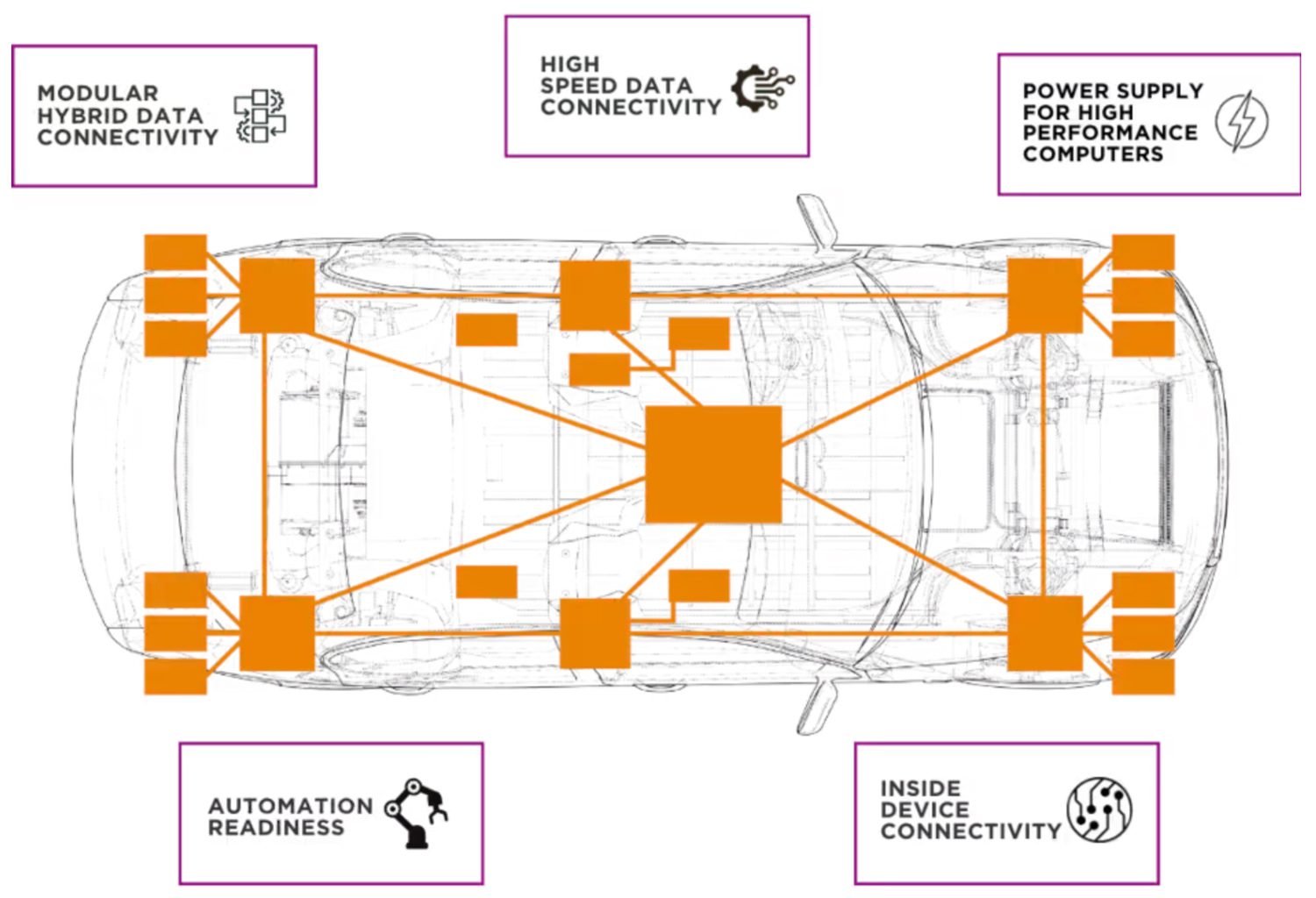

As autos evolve into high-tech ecosystems, dependable and sturdy connectivity is crucial to make sure seamless communication between zones and programs. Connectivity choices may even want to offer space-saving options to serve the upper variety of connections throughout fewer high-power management items whereas offering a better degree of modularity to assist extra flexibility.

TE Connectivity (TE), a worldwide business expertise chief, is on the forefront of this revolution, delivering cutting-edge automotive options designed with scalability, sustainability, and automation in thoughts. TE’s portfolio combines engineering excellence with sensible innovation, making certain automakers have the instruments to construct autos for generations to come back.

TE’s connectivity improvements are particularly designed to allow subsequent era automobile structure transformation:

- Area-saving designs: Te Modular Hybrid System (MHS) options versatile plug and heard configurations and is scalable for any automobile platform. It delivers as much as a 40% discount in each house and weight and makes use of the most recent sustainable supplies, recycling processes and is automation-ready. The GenY 68P Sealed Hybrid Inline Connector combines sign, energy and information connectivity right into a single hybrid answer, supporting OEMs by streamlining connector consolidation, reduce provide chain complexity, and obtain financial savings in price, weight, and house.

- Automation-ready options: TE’s connectors are designed to simplify manufacturing and meeting, improve reliability, accuracy and traceability.

- Energy developments: Te 48V-ready connectors are engineered to ship protected, dependable and environment friendly energy distribution, supporting the transition from 12V programs to satisfy the rising vitality calls for extra successfully. This shift improves total efficiency, reduces weight and value, and facilitates nice system automation.

- In-device connectivity: Inside gadget connectivity is crucial for zonal controllers, facilitating communication between zones and related subsystems in addition to centralized processors. This allows a unified framework the place a central processor can entry information from all sensors and actuators.TE presents an expansive portfolio of automotive grade options together with flex-to-board, board-to-board, wire-to-wire, and wire-to-board choices.

- EMI Shielding: Subsequent-gen E/E architectures embrace a variety of electronics, lots of which have a excessive danger of propagating Electromagnetic Interference (EMI). It’s important to contemplate EMI/RFI shielding options that successfully cut back susceptibility to digital malfunctions by both blocking exterior electromagnetic waves or stopping the emission of inside electromagnetic waves that might intervene with surrounding circuits or units. Such malfunctions may vary from the innocuous, resembling an odd noise on a automobile radio to extra critical incidents, resembling accidents ensuing from the failure of security gear. As autos combine extra superior electronics, efficient EMI shielding to addresses vulnerabilities in any respect ranges of design from the PCB format to the enclosure making certain sign integrity, reduces cross-talk, and maintains dependable operation of safety-critical capabilities. TE presents a broad portfolio of EMI shielding supplies together with conductive elastomers, connector gaskets, fabric-over-foam and conductive foams which can be designed to optimize efficiency and compliance in superior driver help and different important automotive programs

The Significance of an Skilled Associate

With a long time of experience and a complete vary of connectivity options, TE is ready to simplify complexity, improve effectivity, and empower designs — making certain OEMs and suppliers can navigate this evolving panorama with autos to satisfy the calls for of right this moment and tomorrow. Join with TE right this moment to see how our options and experience are empowering the automotive business to create smarter, safer, and extra related autos.

TE Connectivity: Offering cutting-edge connectivity merchandise and applied sciences for subsequent era automotive functions.