Dürr and GROB have introduced a brand new lithium-ion battery cell idea manufacturing facility. The system targets the EV phase, that includes dry electrode coating and a sophisticated Z-folder cell meeting with built-in notching.

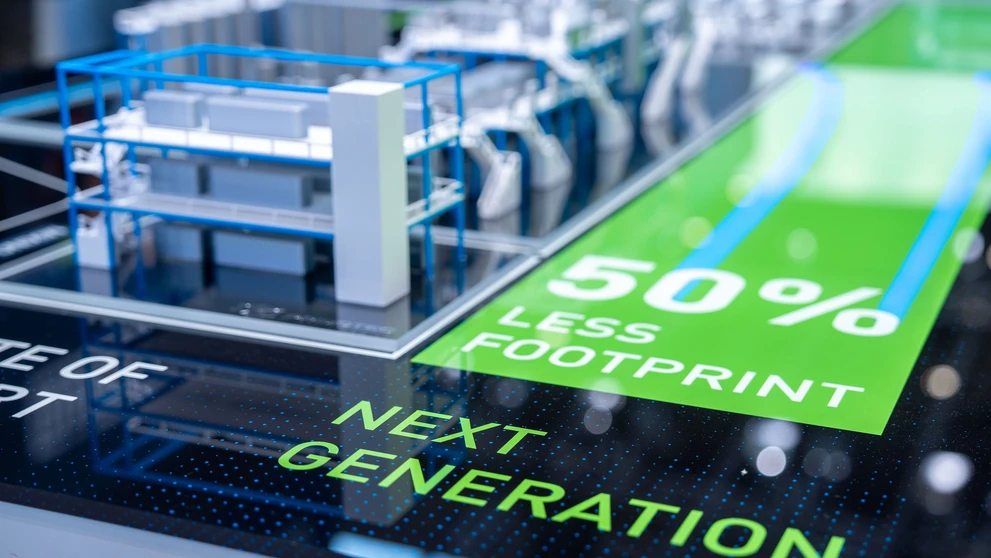

In line with Dürr, the idea manufacturing facility reduces manufacturing area necessities by 50 p.c and cuts vitality consumption by 70 p.c in comparison with conventional strategies. Key applied sciences embrace dry coating of electrodes—particularly, Dürr’s X.Cellify DC household, which makes use of a dry-mixed energetic materials pressed right into a free-standing movie through calender machines. This course of employs the Activated Dry Electrode know-how from LiCAP Applied sciences, eliminating the necessity for a drying course of and solvent restoration. Extra movie materials will be totally returned to manufacturing earlier than lamination, lowering waste.

The dry coating proof of idea has demonstrated constant high quality and is scalable, with a proof-of-concept plant working in a dry room at Ingecal in southern France. Dürr is now looking for pilot companions amongst business gamers for gigawatt-scale tasks.

In the meantime, GROB’s new era Z-folder for cell meeting integrates notching, attaining 95 p.c system availability and additional rising throughput whereas minimizing area wants. The separator is exactly dealt with with low net stress, which improves reliability.

Along with electrode processing, Dürr studies a brand new methodology for electrolyte filling of battery cells, the place electrolyte is added at as much as 30 bar—two to a few occasions larger than commonplace business pressures—enabling extra exact dosing and sooner filling. For the basic moist coating course of, Dürr has additionally enhanced automation and course of management. Sensors present 0.5 micrometer accuracy in calendering, and laser dryers ship a 50 p.c improve in net velocity.

Digital instruments are additionally integral, as Dürr and GROB provide digital mapping and simulation of the manufacturing facility, supporting manufacturing planning and high quality evaluation via manufacturing execution system/manufacturing operations administration (MES/MOM) software program from Dürr’s iTAC subsidiary.

“With our expanded portfolio of extremely obtainable machines and programs, we collectively cowl nearly your complete worth chain for battery cell manufacturing with our personal applied sciences,” stated German Wankmiller, CEO of the GROB Group.

Dürr is consolidating its electrode coating and electrolyte filling merchandise beneath the brand new X.Cellify platform.

Supply: Skinny