Sponsored by dSpace.

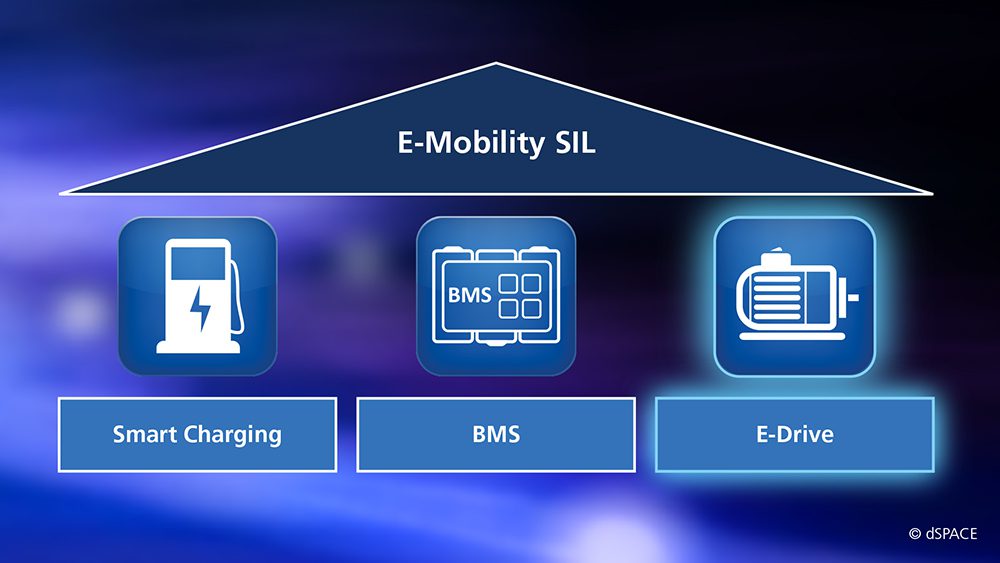

Electromobility is evolving quickly. New car ideas, advanced E/E architectures, and more and more highly effective battery programs are pushing builders to their limits. On the similar time, the strain to shorten growth cycles and cut back prices is rising. On this dynamic atmosphere, one technique is gaining important traction: Software program-in-the-Loop (SIL) testing.

What Is Software program-in-the-Loop Testing?

SIL testing refers back to the digital validation of ECU features utilizing simulation fashions—with none bodily {hardware}. The ECU software program runs in a digital atmosphere and interacts with a digital twin of the car or subsystem. This permits engineers to check features early, establish errors, and cut back growth dangers.

Why SIL for Battery Electrical Autos?

Battery electrical automobiles (BEVs) are notably advanced: battery administration programs (BMS), charging features, thermal administration, and power administration should work seamlessly collectively. SIL testing allows:

- Early validation of management algorithmscorresponding to for power administration, charging, and thermal administration.

- Simulation of charging infrastructure and sensible chargingtogether with communication protocols like ISO 15118-20.

- Testing of Battery Administration Techniques (BMS), Simulation of cell habits and fault circumstances to validate security and effectivity algorithms.

- Integration of recent E/E architecturescorresponding to zonal controllers or centralized car computer systems.

Benefits Over Conventional Testing Strategies

SIL testing is particularly highly effective in early growth phases. It helps parallel testing, automated regression testing, and seamless integration into CI/CT pipelines. Its scalability permits groups to run 1000’s of check instances throughout a number of digital environments concurrently, whereas virtualization allows testing of whole software program stacks—together with middleware and working programs—with out the necessity for bodily ECUs. The total potential of SIL unfolds by its scalability in cloud purposes, which allows the parallelization of exams and thus elevated check protection and pace.

New E/E Architectures: Challenges and Alternatives

Trendy automobiles more and more depend on zonal architectures, the place features are centralized somewhat than distributed throughout particular person ECUs. This brings advantages by way of weight, value, and replace functionality—but in addition introduces new validation challenges like modelling the {hardware} dependencies of ECUs.

SIL testing provides:

- Modularity: Particular person software program parts may be examined in isolation.

- Flexibility: Architectural adjustments may be shortly simulated and evaluated.

- Reusability: Fashions and check situations may be reused from SIL to HIL, the place as much as 80% of exams may be executed earlier than the primary bodily ECU exists.

- Virtualization help: Allows testing of containerized purposes and service-oriented architectures.

Integration into the Growth Workflow: From Code to Suggestions in Seconds

One of many key strengths of SIL testing lies in its seamless integration into trendy growth pipelines. With a robust API, the whole course of—from making a digital ECU (VECU) to executing automated exams—may be absolutely scripted and embedded into present toolchains.

This implies builders can set off exams immediately from their growth environments or any CI/CT system. Artefacts generated from supply code are mechanically constructed, deployed, and examined—offering immediate suggestions on whether or not the implementation behaves as anticipated. This suggestions loop may be a part of a pull request, making certain that each code change is validated earlier than integration.

Much more compelling, OEMs can prolong this strategy to their provider networks. At any time when a provider submits an replace, it may be uploaded as an artefact to the cloud and mechanically examined throughout the full digital car context. This cloud-based validation workflow allows scalable, distributed testing throughout organizational boundaries—with out requiring bodily infrastructure or guide coordination.

The power to run full-vehicle simulations within the cloud additionally opens the door to on-demand compute scaling, distant collaboration, and steady integration throughout world groups. These capabilities are important for contemporary growth organizations trying to speed up innovation whereas sustaining high quality and compliance.

SIL Throughout the Growth Lifecycle

Whereas Software program-in-the-Loop testing is usually related to early-stage growth, its advantages prolong throughout the whole lifecycle of car software program. With dSPACE’s SIL options, groups can:

- Validate software program updates constantlyeven after SOP, by integrating SIL into over-the-air (OTA) replace pipelines.

- Assist variant administrationby testing a number of configurations and have units in parallel.

- Carry out integration testingby combining a number of VECUs and FMUs right into a full system simulation.

- Allow long-term regression testingmaking certain that new options don’t break present performance.

This lifecycle protection is particularly beneficial in agile growth environments, the place software program is delivered incrementally and have to be validated constantly. With VEOS and its cloud-native capabilities, these exams may be executed at scale on-demand, throughout groups, and with out {hardware} bottlenecks.

System-Degree Integration with VEOS: Past Perform Testing

Whereas SIL testing is usually related to function-level validation, the dSPACE VEOS platform goes far past that. It allows system-level integration by supporting a variety of abstraction ranges. The abstraction stage of a V-ECU offers details about its growth standing. In terms of simulation, the next applies: The additional the event of the V-ECU progresses, the extra particulars should be taken under consideration.

- Degree 0 and stage 1: Within the early phases of growth, the main focus is on validating particular person software parts. The precise sort of sign transmission between V-ECUs is secondary and is often not but absolutely specified.

- From stage 2: Bus communication and the combination of the V-ECU into an general simulation have gotten more and more necessary. From right here, fundamental software program for bus communication have to be built-in into the V-ECU. For simpler integration and quicker creation of the V-ECU, simplified fundamental software program that solely contains the communication (COM) module is often utilized in earlier growth phases.

- Degree 3: These V-ECUs come very near the actual ECU and ideally solely differ by way of the hardware-dependent driver modules. All fundamental software program positioned above these modules is a part of the check object right here and is subsequently absolutely built-in into the V-ECU.

This layered strategy permits builders and integrators to pick out the best stage of constancy for his or her use case, and to steadily evolve their digital check atmosphere because the software program matures. VEOS helps all these ranges and allows their mixture in combined configurations, making certain flexibility and scalability all through the event lifecycle.

VEOS is designed to be open and interoperable. It helps integration with third-party simulation and testing platforms, making it attainable to construct hybrid environments that mix dSPACE instruments with exterior options. Whether or not you’re working with proprietary fashions, open requirements, or industrial software program, VEOS offers the pliability to carry all the things collectively in a single cohesive simulation.

VEOS additionally helps cloud-native deployment fashions, making it attainable to run simulations and exams in scalable cloud environments. This permits organizations to shift from native, hardware-bound setups to versatile, cloud-based validation platforms that help distant entry, elastic compute, and world collaboration.

This openness is a key differentiator: it permits OEMs and suppliers to collaborate throughout instrument boundaries, validate throughout domains, and scale testing throughout platforms—with out being locked right into a single ecosystem.

Open Requirements and Toolchain Compatibility

dSPACE SIL options are constructed to combine seamlessly into heterogeneous toolchains. VEOS helps trade requirements corresponding to:

- FMI (Purposeful Mock-up Interface) for mannequin trade and co-simulation.

- ASSAM KIL for standardized check automation.

- AUTOSAR Traditional and Adaptive for ECU software program integration.

This standards-based strategy ensures compatibility with third-party instruments and permits prospects to leverage present investments in modeling, testing, and automation infrastructure.

Scalable Deployment: From Desktop to Cloud

One of many key differentiators of the dSPACE SIL ecosystem is its scalable deployment mannequin. Whether or not operating regionally on a developer’s workstation or in a high-performance cloud atmosphere, VEOS adapts to the wants of the challenge and group.

- Native execution is right for debugging, and interactive growth.

- Cloud-based execution allows large-scale regression testing, parallel situation validation, and world collaboration.

This flexibility permits groups to start out small and scale up as wanted—with out altering instruments or workflows. Mixed with containerization and orchestration help, VEOS may be built-in into enterprise-grade infrastructures, supporting DevOps practices and steady validation pipelines.

By bridging the hole between desktop simulation and cloud-native testing, dSPACE empowers organizations to construct resilient, scalable, and future-proof validation environments—prepared for the calls for of next-generation car growth.

Conclusion: Digital Validation as a Key to Scalable, Collaborative Growth

Software program-in-the-Loop testing is greater than only a instrument—it’s a strategic enabler for electromobility. It permits for quicker innovation, larger high quality, and decrease prices. Particularly for battery electrical automobiles and new E/E architectures, SIL testing is a vital a part of trendy growth workflows.

With VEOS, dSPACE provides a robust, open, and scalable platform that helps full system integration, cross-tool collaboration, and cloud-based validation pipelines—empowering builders and organizations to form the way forward for mobility collectively.

dSPACE empowers builders worldwide to unlock these advantages—with highly effective instruments, deep experience, and a transparent give attention to the way forward for mobility.