The Implementation of Laser Drying Processes for Economical & Ecological Lithium Ion Battery Manufacturing (IDEEL) analysis venture in Germany developed a laser-assisted roll-to-roll (R2R) drying course of that would scale back the price of lithium-ion battery manufacturing, in keeping with German analysis group Fraunhofer FFB.

The hybrid course of combines typical, oven-based convection drying with laser drying primarily based on high-power diode lasers. It achieves an internet velocity of 30 meters per minute and reduces drying instances by greater than 60% whereas sustaining the identical high quality of outcomes.

The laser booster initially of the method halves the required oven size, lowering the necessity for energy-intensive drying rooms and lowering operational prices by 20-30%.

This method permits the brand new course of for use in current crops, which may then be retrofitted with laser modules.

The IDEEL venture, which was accomplished on December 31, 2024, after a three-year time period, regarded for various drying processes utilizing extremely environment friendly large-area laser irradiation.

The venture was supported by the Federal Ministry of Training and Analysis as a part of the Battery 2020 funding program and was carried out beneath the management of Laserline.

The Fraunhofer FFB participated with the Manufacturing Engineering of E-Mobility Parts (PEM) middle at RWTH Aachen College, Coatema Coating Equipment, Optris, the Fraunhofer Institute for Laser Expertise (ILT) and the Münster Electrochemical Power Expertise (MEET) Battery Analysis Middle on the College of Münster.

The main target of the IDEEL analysis collaboration was initially the event and step-by-step optimization of an applicable laser drying course of. For this function, new supplies for anode and cathode coatings had been particularly designed for laser functions, and aqueous formulations primarily based on graphite, lithium iron phosphate, and silicon-graphite had been efficiently examined at PEM and MEET.

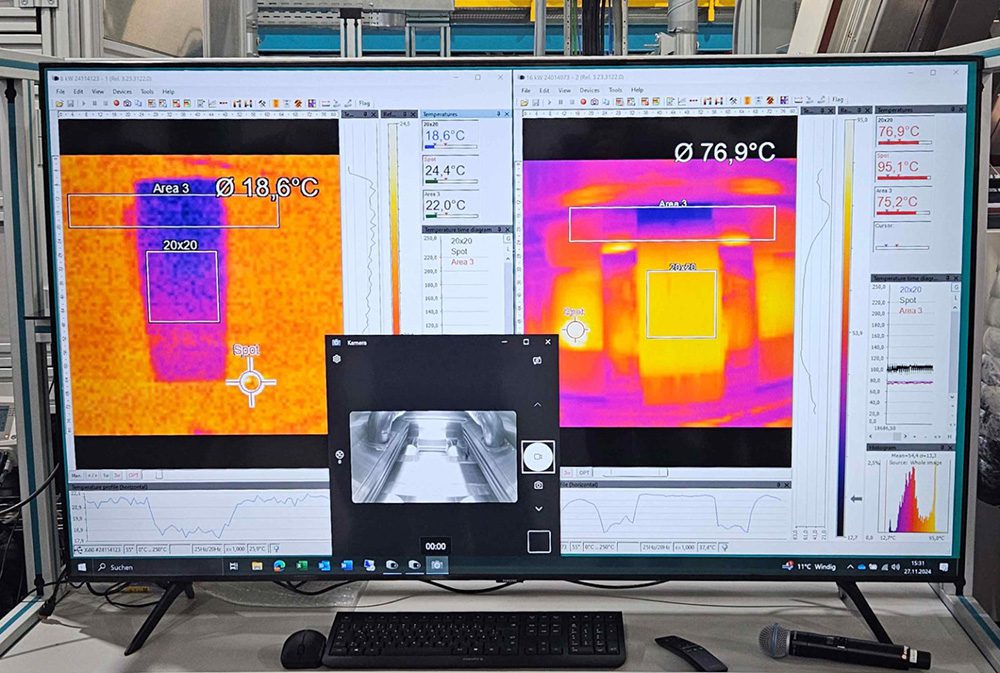

A high-efficiency diode laser system with {an electrical} effectivity of over 50% and a brand new processing optics with coaxial thermography coupling and an oblong laser spot over 0.5 meters broad provided by Laserline was used as the warmth supply. Optris, Laserline and Fraunhofer ILT developed a extremely built-in thermography digital camera with industry-PC-compatible knowledge output for contactless, computerized course of monitoring and management, making certain a continuing adherence to the goal temperature at various net speeds and coating thicknesses.

Coatema developed a modular laser drying unit with a specialised air idea and customized double-chamber wide-slot nozzles for the quick and safe software of water-based battery slurries. Inside this demonstrator, the laser-based R2R drying course of was scaled to industry-standard feed speeds, and Fraunhofer decided and validated the optimum course of configuration.

The hybrid course of developed inside the IDEEL venture will probably be built-in into the work of Fraunhofer FFB, which is to be expanded into the event middle for contemporary battery cell manufacturing for Germany and its European companions.

Supply: Fraunhofer FFB