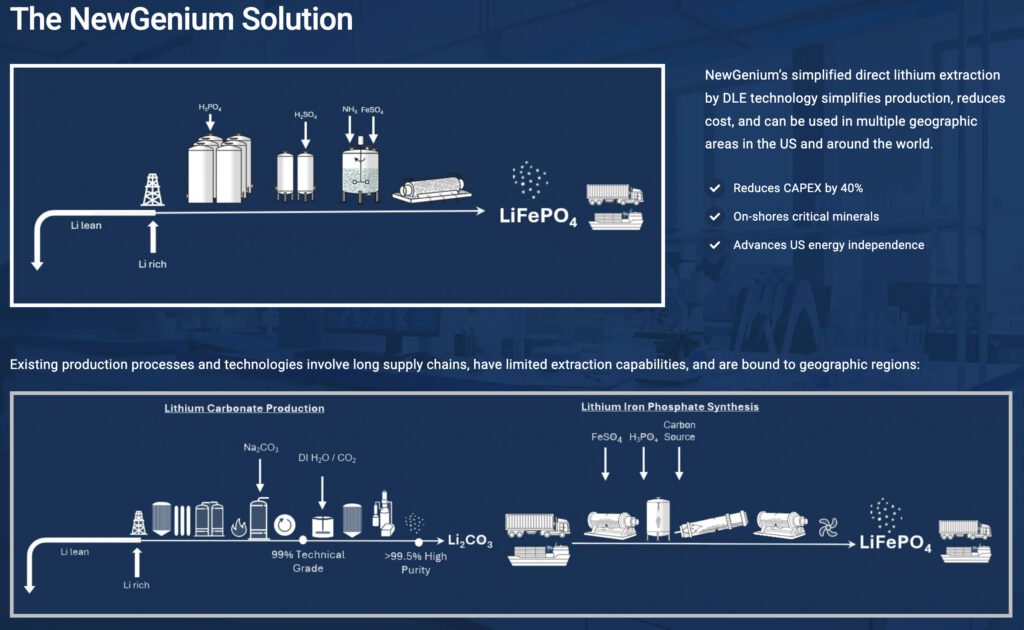

NewGenium, a expertise firm based mostly in Pasadena, California, has introduced its SuperSynth course of, a direct brine-to-lithium-iron-phosphate (LFP) manufacturing expertise. In line with NewGenium, SuperSynth reduces the fee and complexity of LFP manufacturing by enabling extraction of lithium immediately from brine, consolidating extraction and synthesis steps and eliminating the necessity for offshore processing. The corporate stories that its proprietary course of presents a scalable path to home LFP cathode manufacturing for lithium-ion batteries.

The expertise streamlines LFP manufacturing to 3 low-temperature unit operations utilizing widespread course of gear. NewGenium claims the strategy yields considerably much less stable waste and achieves a levelized value of roughly $3 per kilogram of LFP—considerably decrease than the present $5 to $15 per kilogram market charge, which incorporates duties and tariffs. NewGenium’s ion change direct lithium extraction (DLE) and in-lab LFP manufacturing had been confirmed at its Monrovia, California facility in 2025.

Goal purposes for SuperSynth embody US-based upstream nicely operators and downstream cathode and battery producers, significantly these producing battery packs for electrical autos and battery vitality storage techniques. NewGenium says its course of addresses a key problem in US battery provide chains: changing home lithium-rich brines into battery-grade LFP cathode materials with out counting on worldwide processing or imports. The corporate references a 2024 US Geological Survey examine estimating as much as 19 million tons of lithium in US brine reserves, sufficient to help present demand for practically 100 years.

Conventional strategies usually generate lithium carbonate by way of evaporation ponds, which require substantial land and multi-year processing intervals adopted by worldwide transport for LFP synthesis. NewGenium’s course of is positioned instead that consolidates and simplifies this provide chain.

“The USA faces a essential second wherein the exploding demand for lithium batteries will not be matched by our capability to provide the mandatory LFP cathode supplies,” mentioned Christopher Murphy, CEO at NewGenium. “Given the brand new mandates for vitality and significant mineral independence, the nation’s battery trade should reap the benefits of home reserves and produced water utilizing DLE applied sciences. We’re thrilled to have developed a novel chemical course of that can assist the USA construct nationwide independence in essential minerals by extracting lithium from brine and turning it into LFP in a simplified method. Maybe most fun is the truth that onshoring USA home manufacturing of LFP batteries from brine lastly turns into each financially and environmentally engaging.”

Supply: NewGenium