Sponsored by Avery Dennison.

Continued optimization of battery design means addressing thermal runaway and different points. Strain-sensitive adhesive (PSA) tapes could also be an vital a part of the answer.

By Max VanRaaphorst—Market Supervisor, Vitality Storage for Avery Dennison North America.

It is a dynamic time for the electrical automobile (EV) market. In accordance with an April 2025 report by Cox AutomotiveEV gross sales rose 11.4% within the first quarter of 2025 in comparison with the primary quarter of 2024. Many long-term forecasts predict continued double-digit progress.

The near-term outlook for the business, nevertheless, is volatility. As of this writing, the Trump administration’s tariff plan stays in flux. No matter their last type, tariffs appear more likely to stir the worldwide provide chains that producers depend upon.

Regardless, engineers tasked with making EV batteries safer, extra sturdy, and extra energy-dense should stay targeted on the duty at hand. Actually transformative applied sciences, similar to solid-state batteries, are nonetheless years off. So, continued progress means additional optimization of present know-how platforms. Strain-sensitive adhesive (PSA) tapes, built-in with useful supplies, are a flexible, easy-to-use, and cost-effective materials answer for a lot of of right now’s EV battery engineering challenges.

The thermal administration ecosystem

A key problem on this story of optimization is that of thermal administration.

A battery is a posh ecosystem requiring temperature regulation for optimum cell efficiency throughout regular use in addition to throughout excessive occasions. On the most simple degree, meaning cells ought to be warmed once they’re too chilly and cooled once they’re too heat.

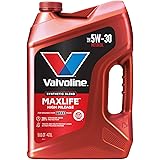

Batteries thus have three kinds of thermal necessities:

1. Thermal insulation

Low thermally conductive (insulating) supplies are used to guard usually working cells from overheating, thus stopping thermal runaway occasions.

2. Thermal conductivity

Excessive thermally conductive supplies, similar to thermal interface supplies (TIMs), are used to attach cells to cooling elements and facilitate warmth switch.

3. Venting

Venting methods enable sizzling gases to flee a malfunctioning cell whereas defending adjoining cells. These methods can incorporate numerous thermal supplies.

To know thermal conductivity … go for a hike within the woods

Examine the thought of thermal conductivity to a hike within the woods. Think about attempting to bushwhack by a dense forest of timber, low-lying scrub, roots and rocks, and maybe some mud. It’s tough, you’re respiration onerous, sweating and perhaps cursing a bit! Now examine that to a stroll on a flat, well-maintained, tree-lined path. It’s simpler and doubtless extra pleasurable. From warmth’s perspective, a low conductivity materials is like that dense forest — tough to traverse. A excessive conductivity materials is the light path.

One other vital consideration is the size of the hike itself. A brief hike by a dense forest might not be a lot of an impediment. It’s the lengthy slog that finally slows you down.

That brings us to PSA tape options for thermal administration. Tapes, by design, are very skinny. So whereas they don’t have a tendency to supply excessive thermal conductivity, they do supply only a brief path for warmth to journey. However as a consequence of their large versatility, tapes will also be built-in with low thermal conductivity supplies, thus making them appropriate for a variety of thermal administration purposes inside a battery pack.

Thermal runaway barrier options

Thermal runaway begins when an overheating cell combusts. That fireplace grows to the purpose at which sizzling gases and supplies burst from the cell. The escaping matter causes different cells to overheat, catch fireplace and burst in flip. A module-level thermal runaway occasion can then unfold to different modules in a pack, inflicting full destruction of the battery pack and sure the automobile.

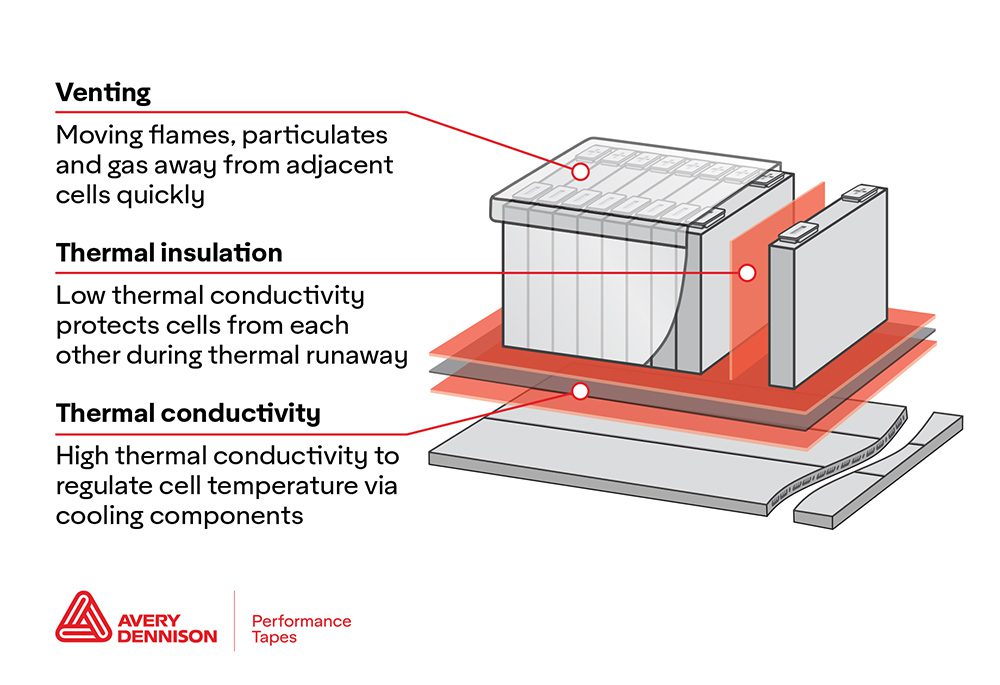

Tapes can be utilized to encapsulate insulating (low warmth conductivity) barrier supplies, similar to mica, ceramic paper or aerogels. These can then be positioned between cells, modules, and/or on the within of the pack lid. Due to tapes’ skinny profiles, they’re a great selection for these slim areas — offering the mandatory bond whereas permitting for the utmost potential thickness of the insulating materials given the area constraints.

In some circumstances, these PSA-based options can stop cell- or module-level thermal runaway propagation. However generally, they will not less than gradual the unfold of thermal runaway, offering helpful time for passengers to exit the automobile.

Thermal runaway venting options

As famous above, thermal runaway is underway when sizzling gases and supplies erupt from a single cell. Cell producers thus combine venting methods into their designs.

A vent is solely a port that permits sizzling, increasing gases and burning materials to flee the cell’s confines, making a extra managed stress launch. The issue lies in the truth that as these escaped rush by the module, they will infiltrate different cells by their vent ports, and thus provoke a thermal runaway occasion.

What’s wanted is a venting technique that permits that stress launch whereas defending wholesome cells from these sizzling gases and supplies. Once more, PSA tapes supply a sublime answer: On this case, it’s tapes with an anisotropic service—only one facet of the tape provides flame resistance.

These PSA tapes are utilized to battery cells throughout meeting, overlaying the vent ports. The anisotropic service then permits flames to flee by the port of a burning cell. However because the flames then flow into by the module, the flame-retardant facet of the tape protects the vent ports of wholesome cells.

PSA-based anisotropic tapes may help shield wholesome cells and inhibit thermal runaway.

Flame retardance isn’t everlasting. Ultimately, the tape is compromised, and flames can have an effect on wholesome cells. However once more, that is about mitigating and delaying full thermal runaway, and giving passengers helpful time for a secure escape.

Dielectric safety options

Electrical arcing in a high-voltage atmosphere can usually result in fireplace, and thus is one other challenge that may have an effect on a battery ecosystem’s thermal administration. Once more, PSA tapes are stepping as much as the problem.

Polymer movie tapes can be utilized throughout the pack and module for bonding or to encapsulate important components. These tapes supply excessive dielectric power per unit thickness and have a tendency to inhibit warmth movement, making them a most popular various to many conventional dielectric coatings.

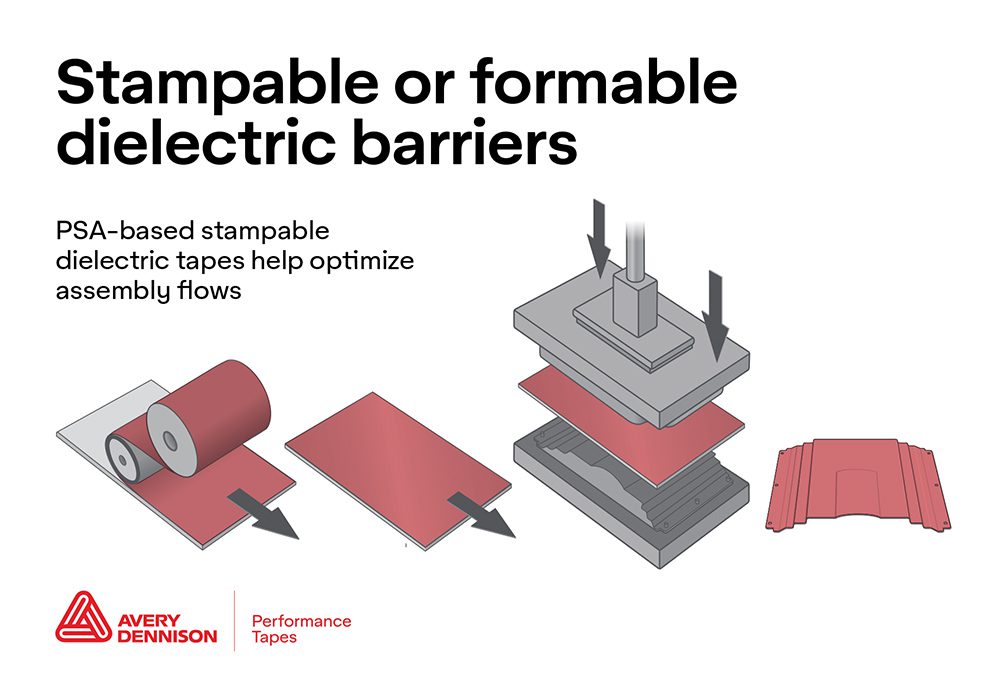

A brand new PSA tape know-how is a dielectric tape that may be utilized to flat metallic blanks previous to stamping and forming. It’s an easy-to-use answer that optimizes each dielectric power and meeting flows, because it eliminates curing and cleansing, and different processes wanted for conventional coatings. Avery Dennison has just lately revealed a whitepaper explaining how stampable dielectric PSA tape know-how can profit producers.

PSA tape options can be found now

The entire PSA tape options mentioned on this article are presently out there. In truth, the Avery Dennison EV Battery Portfolio incorporates a variety of PSA tape-based options engineered to assist producers deal with points similar to thermal runaway and dielectric safety. And these tapes are straightforward to include into both handbook or automated meeting processes, serving to EV battery producers optimize each workflow and design.

Tape options might be reduce and stamped to spec and offered at scale by native converters. These third-party suppliers work intently with Avery Dennison and the battery producer to make sure the best options are offered on the volumes wanted, even in a unstable time for the automotive business.

A vivid future for EVs

No matter volatility the close to time period may maintain, the long run is vivid for EVs. Through the use of options similar to PSA tapes, producers might be assured their merchandise will meet customers’ wants for security, reliability and sturdiness.