Germany’s Schaeffler Group manufactures an unlimited number of “movement know-how” merchandise, together with many EV elements. The corporate lately launched a number of new merchandise aimed on the electrical development equipment market. Electrical drive techniques are more and more displaying up on development websites, notably in Germany, the place some native governments have banned legacy ICE autos from city websites.

Schaeffler has launched a brand new line of 800 V liquid-cooled heavy-duty electrical motors for all-electric and hybrid drive techniques. These obtain particularly excessive torques, a power-to-weight ratio (peak) of round 5 to 7 kW/kg, and most efficiencies of greater than 97% in a velocity vary of three,000 to eight,000 rpm. “The low losses of the drive motors are important to permit lengthy working occasions between charging cycles on development websites and guarantee environment friendly use of power,” Shaeffler explains.

The modular motor collection consists of three variants with most outputs of 125, 299 and 315 kW. The one distinction is the size of the energetic components. The person stator laminations and the A- and B-side bearing finish shields of the motors are an identical in every case, thus facilitating cost-efficient manufacturing. The stator windings are designed as flat wire (steady hairpin) windings, often known as wave windings.

Not too long ago, at bauma, Schaeffler additionally demonstrated a whole electrical axle with built-in heavy-duty electrical motor.

The offroad sector of Schaeffler’s Bearings & Industrial Options division now affords a complete vary of electrical drives with steady output of 1 to 300 kW for the development tools trade. Schaeffler can provide a variety of active-part elements and full techniques similar to wheel-hub drives primarily based on everlasting magnet synchronous machines. All essential manufacturing applied sciences additionally come from a single supply: the stator laminations stamped in-house, the hairpin and wave winding know-how, the mechanically produced coil windings, and the HV plug connector techniques.

Different Schaeffler merchandise aimed on the off-highway EV market embody:

- Electromechanical linear actuators. The CAHB10 and CAHB2x actuators, with rated forces of as much as 10 kN, had been particularly developed for auxiliary features in off-road purposes, similar to earth-moving and street tools. Typical purposes embody sign mild adjustment, ergonomic seat adjustment, opening and shutting of heavy covers and engine hoods, roof top adjustment, swiveling of cabs and elevating of jibs.

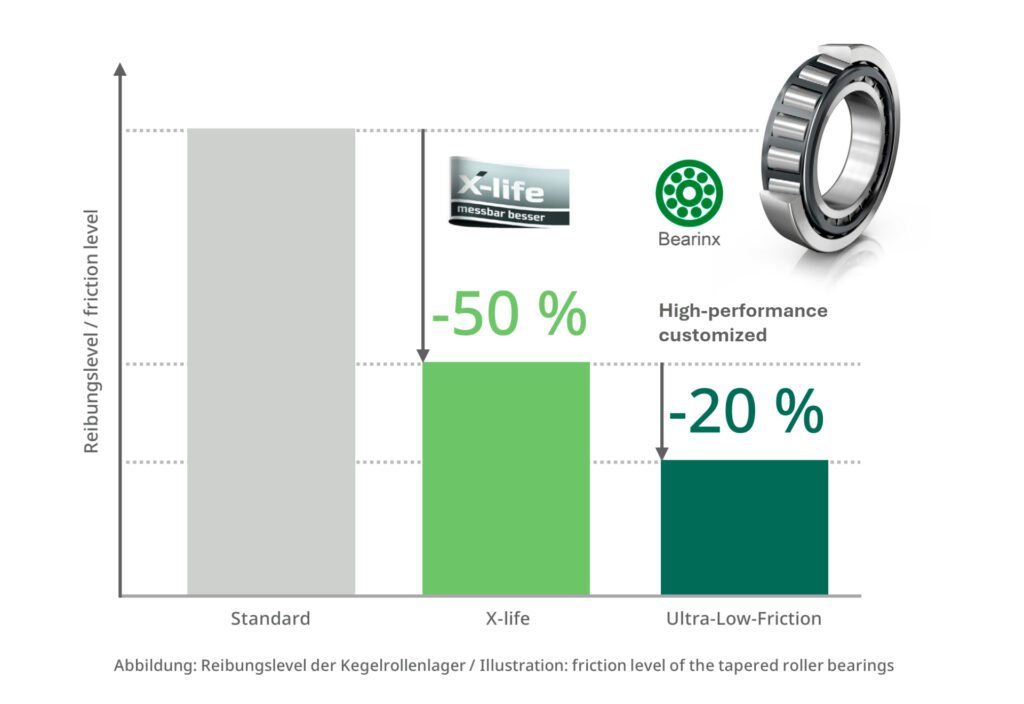

- Low-friction curler bearings. Rolling bearings inherently provide low friction, however Schaeffler’s growth engineers have been capable of considerably scale back friction much more by means of focused optimization measures. Cylindrical curler bearings might be preferrred to be used in built-in planetary gear bearing preparations. They provide a significant benefit in purposes with minimal set up area and excessive radial load. Diminished friction can have a direct impression on the power consumption and thus the emissions of development equipment.

- Sensors. With a purpose to push development equipment to its efficiency and loading limits whereas avoiding machine breakdowns, the stress on machine elements must be measured. Schaeffler’s torque measurement modules seize information throughout operation, and transmit it by way of an analog or CAN-bus interface, permitting the info for use for optimized management of working features, for security features, and for needs-based upkeep. The Schaeffler LoadSense-Pin permits stresses in metallic elements to be measured, so vital working circumstances and cargo peaks might be recognized and working prices diminished.

- Upkeep-free plain bearings for kingpins and chassis joints. Kingpins and chassis joints are subjected to excessive forces and robust shock masses, making them topic to false brinellinga put on phenomenon brought on by inadequate lubrication within the rolling contact. At bauma, Schaeffler launched a brand new idea to switch tapered rolling bearings on kingpins and chassis joints with maintenance-free, dry-running plain (sleeve) bearings. These patented bearings are fitted with the Elgoglide sliding layer, which withstands dynamic contact pressures of as much as 300 N/mm2.

Supply: Schaeffler