Sponsored by Avery Dennison.

A conformable dielectric tape answer

EV battery pack voltages are growing, leading to higher pack power density and improved automobile efficiency. With this enhance, nonetheless, comes a higher want for dielectric options that aren’t solely dependable and sturdy, however complement fashionable pack design and the wants of producing processes.

The Avery Dennison Volt Powerful™ Portfolio of dielectric PSA tapes for EV batteries addresses these wants. The following-generation Volt Powerful™ Stretch providing supplies producers with a dielectric answer that’s stampable, conformable, resistant to ripping, and accommodates the warmth move wants throughout the pack.

Prevention {of electrical} arcing in EV battery packs is vital

The evolution of EV battery pack voltage and power density has been pivotal in enhancing automobile efficiency and vary.

At present’s EVs make the most of battery packs working at 400V or 800+V. This permits sooner charging instances and extra environment friendly energy supply to the motor. Concurrently, enhancements in power density — the quantity of power saved per unit of mass or quantity — have allowed for lighter, extra compact battery packs that may retailer extra power.

Prevention {of electrical} arcing has all the time been a core security concern in battery pack design. With this development in pack efficiency, nonetheless, prevention has grow to be crucial to forestall quick circuits; thermal runaway; or electrical hazards for the motive force, passengers, and repair technicians.

An outline of conventional dielectric safety options

Sturdy, cost-effective dielectric safety options are thus wanted, and EV battery producers have employed quite a lot of strategies. The commonest are dielectric coatings (utilized by spraying or dipping), or pressure-sensitive (PSA) tapes using dielectric movies resembling PET or polyimide.

These coatings and tapes may be utilized to the inner elements of a battery pack to forestall unintended electrical conduction. They guarantee battery packs can function successfully in various circumstances, bettering their efficiency and longevity, and enhancing driver and passenger security.

Dielectric coatings have loved an added benefit over movie tapes on account of their capability to be simply utilized to stamped steel components with complicated geometries. As producers proceed to evolve their designs, conformability has grow to be an more and more vital requirement for dielectric supplies.

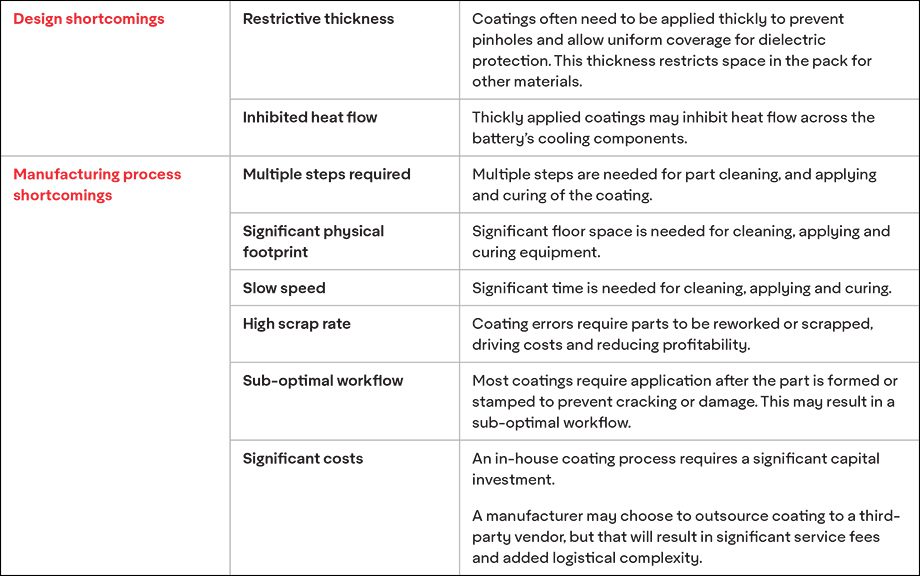

Shortcomings of conventional conformable dielectric options

Dielectric coatings can certainly be efficient electrical insulators in fashionable EV batteries, and they’re extremely interesting on account of their conformability. Nonetheless, these coatings do have shortcomings that may have an effect on the manufacturing course of and the general effectiveness of the battery pack design.

Higher conformable dielectric options are wanted that permit producers to keep away from these shortcomings. PSA tapes with stampable dielectric movies, designed to be stamped and fashioned with their underlying substrates, are simply such an answer.

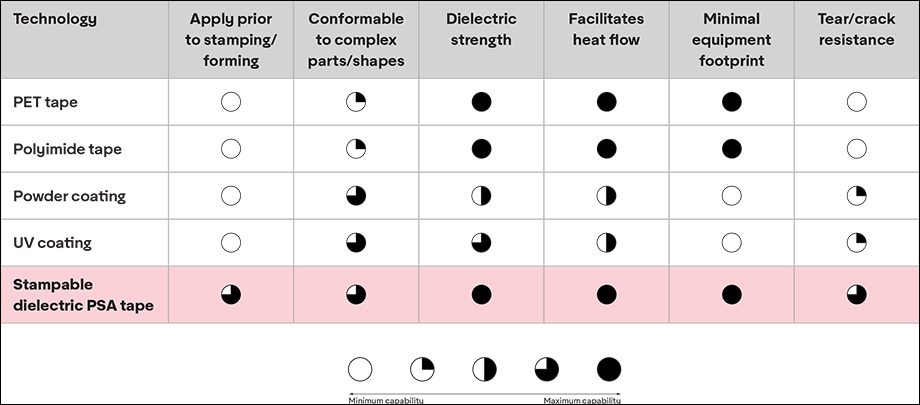

Evaluating stampable dielectric tapes in opposition to competing dielectric applied sciences

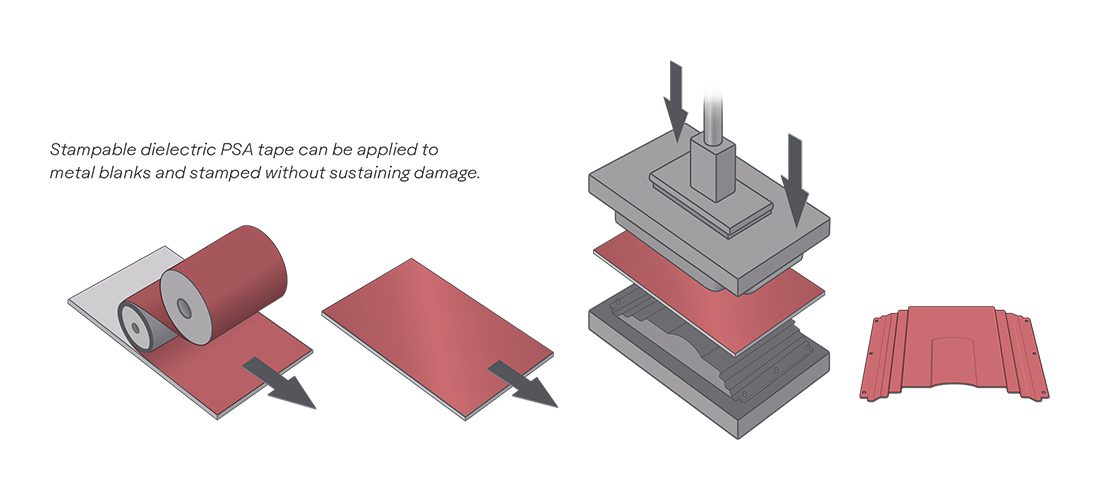

A brand new sort of PSA tape know-how is now accessible that addresses these shortcomings. This tape contains a extremely conformable dielectric movie facestock that’s totally suitable with steel stamping processes.

The tape may be utilized to a steel clean (handbook or automated utility course of), then stamped together with the clean. The result’s a fashioned steel half with dielectric safety already utilized. Not like coatings, the PSA tape and its conformable dielectric movie resist injury or cracking within the press.

In testing accomplished on the Avery Dennison Efficiency Tapes laboratory, an ISO-9000 facility, samples of a PSA-based dielectric safety answer had been utilized to aluminum sheet steel blanks. The samples had been then stamped to check the sturdiness of the tape below varied pressures typical of commercial steel stamping. In all instances, the PSA answer withstood utilized pressures, even in excessive situations when ample stress was utilized to crack the aluminum substrate.

Right here’s how this new know-how compares to conventional dielectric options.

There are a bunch of challenges related to dielectric coatings, together with:

- Restricted meeting line flexibility

- Elevated waste and value

- Lack of conformability to complicated components/shapes

- Restricted area in battery pack on account of dielectric coating thickness

- Giant bodily tools footprint

- Simply torn or cracked

Fortunately, Stampable dielectric PSA tapes present an alternative choice to the above challenges, by the next options:

- Much less labor-intensive course of and sooner meeting line

- Decrease scrap charges and better manufacturing charges

- Stampable tapes mix excessive elongation at break and excessive tear resistance

- Stampable dielectric PSA tape supplies considerably extra dielectric power per unit of thickness in comparison with a typical dielectric coating

- Bodily footprint for tape utility is considerably lower than what’s required for coating utility

- Very excessive elongation at break mixed with excessive tear resistance.

Introducing Subsequent-Technology Volt Powerful™ Stretch | A PSA-based stampable dielectric answer from Avery Dennison

Avery Dennison has developed and launched a PSA-based dielectric safety answer. A part of the corporate’s Volt Powerful™ portfolio, this tape is the subsequent era of the Volt Powerful™ Stretch PSA dielectric tape (Avery Dennison half quantity FT 0031).

This answer is designed to accommodate a variety of wants whereas addressing key challenges for electrical insulation in battery packs. Importantly, this new tape answer is extremely suitable with steel stamping processes and different metal-forming strategies.

Put merely, next-generation Volt Powerful™ Stretch may be utilized to a steel clean, then stamped into a posh form with out vital danger of the tape cracking, tearing, or sustaining some other sort of injury.

Like all PSA tapes, next-generation Volt Powerful™ Stretch is simple to use and reposition, contains a skinny profile, and is sturdy for the lifetime of the battery.

Functions

Subsequent-generation Volt Powerful™ Stretch can be utilized for bonding and safety in varied purposes all through a battery pack. It has been more and more used with cooling plates and pack buildings.

- Pack structural elements

- Versatile and inflexible busbar and cell connection methods in EV battery assemblies

- Varied cooling elements, together with chill plates and cooling ribbons

Avery Dennison options for EV battery manufacturing

The Avery Dennison EV Battery portfolio contains varied purposeful bonding and safety tapes constructed on a number of PSA applied sciences. These are engineered to make EV batteries safer, extra environment friendly and simpler to assemble.

The portfolio may help producers remedy a number of the commonest challenges in battery design and development, together with lowering flammability, boosting dielectric power and design/meeting optimization.

Past bonding

Avery Dennison Efficiency Tapes presents intensive assist past its product portfolio. This contains offering converters and finish customers with entry to testing and collaboration with subject material consultants to develop distinctive options for EV Battery purposes.

Contact Avery Dennison to study extra

In case you’re an OEM, automotive tier provider or converter consultant trying to higher perceive the potential for PSA tapes in EV batteries, please contact us instantly at dustin.winter@averydennison.com or max.vanraaphorst@averydennison.com.

To study extra about Avery Dennison Efficiency Tapes’ options, go to www.tapes.averydennison.com/evbattery.