First large-scale manufacturing of excessive voltage inverter brick for main Chinese language automotive producer

For a few years, Schaeffler has been setting requirements in movement expertise by means of its pioneering improvements and developments. With the launch of quantity manufacturing of the excessive voltage inverter brick in Tianjin, China, Schaeffler has reached an necessary milestone in its electrification technique. This primary quantity manufacturing is for a number one Chinese language automotive producer that’s going to equip its new electrical car fashions with ultra-modern inverter brick expertise.

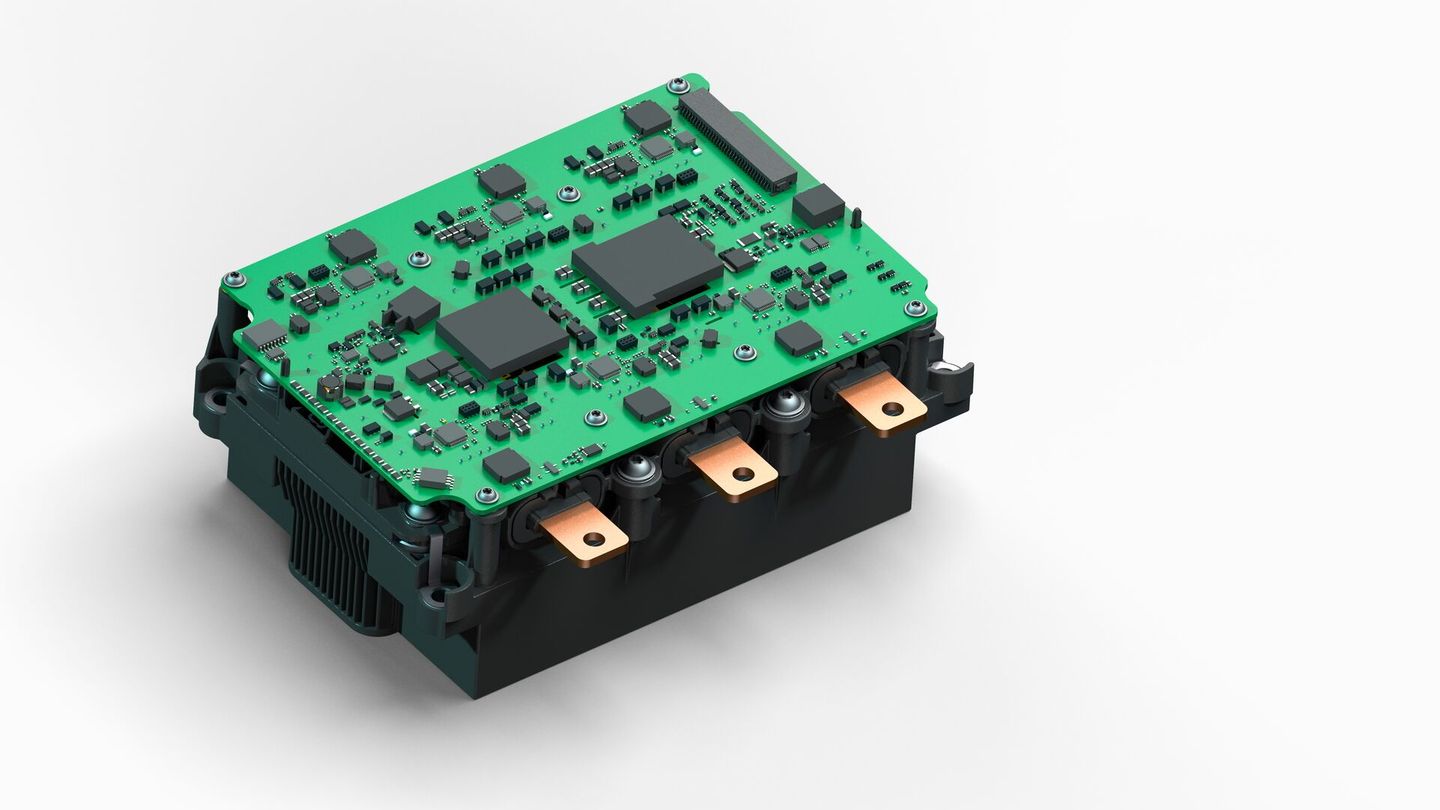

The Schaeffler inverter subassembly is the important energy machine constructing block (brick) to manage the electrical drive by way of logic indicators. That is the place the high-frequency present pulses are produced that set the car’s electrical motor in movement. The efficiency traits of the inverter brick now being produced are spectacular: At buyer’s request, Schaeffler elevated the output of the block by growing the utmost attainable battery voltage to far more than the standard 800 V – and with RMS currents of as much as 650 A, which flip the sub-module right into a compact energy pack.

“By way of our strategic method of incorporating scalability and modularity into our e-mobility options – from particular person elements to a extremely built-in electrical axle – we developed the readily built-in inverter brick. Primarily based on our generic platform growth, it took us only one 12 months to convey this optimum product for the favored X-in-1 architectures in China to quantity manufacturing readiness,” says Thomas Stierle, CEO of the E-Mobility Division at Schaeffler.

Modularity and scalability as the important thing to straightforward integration

As a core element of an inverter, a brick has to satisfy strict necessities. The traits of the sub-module are indicative of the elements behind the present gross sales success and begin of quantity manufacturing: Because of the revolutionary silicon carbide (SiC) energy semiconductor produced by the Schaeffler accomplice ROHM, the frame-mounted sub-module with excessive energy density is compact, environment friendly and readily built-in into numerous inverters because of its modular and scalable design. The sub-module incorporates the facility module for pulse width modulation (PWM) of the present pulses, the DC hyperlink capacitor, a DC hyperlink and a cooler. Furthermore, the brick has a DC enhance operate, because of which a car with 800 V structure can be charged at a 400 V charging station at a charging pace of 800 V. To fulfill the elevated efficiency necessities of the Chinese language automotive producer, ROHM optimized the drain-source voltage of the SiC Chips built-in within the block in keeping with the OEM expectations.

“We’re glad concerning the launch of quantity manufacturing for Schaeffler’s inverter brick with our 4th era SiC energy elements,” says Dr. Kazuhide Ino, Member of the Board and Managing Govt Officer at ROHM. “With our SiC expertise we’re making a considerable contribution to growing the effectivity and efficiency of electrical automobiles. Working with Schaeffler as our accomplice, we’re thus fostering innovation and sustainability within the automotive business,” Dr. Ino provides.

The strategic partnership of Schaeffler (initially initiated underneath Vitesco Applied sciences) with ROHM has existed since 2020 and serves to safe capability for energy-efficient SiC energy semiconductors.

Steady growth of inverter expertise

The inverter brick now in quantity manufacturing is yet one more instance of the technique of creating different sub-modules that was initiated in 2023 with an overmolded inverter. Schaeffler is at present urgent forward with the continuing growth of its inverter expertise with a fair higher diploma of integration for future car structure.

Schaeffler inverter at IAA Mobility 2025

The inverter brick is a part of Schaeffler’s Energy Movement product household, and the inverter expertise will likely be showcased on the Schaeffler sales space at IAA MOBILITY 2025 in Munich. Underneath the banner “The Movement Know-how Firm”, Schaeffler will current its expanded and revolutionary product vary for software program, electrification, drivetrain, chassis, and physique functions on the IAA Summit from September 9 to 12 in Corridor B3, Sales space B40.

SOURCE: Schaeffler