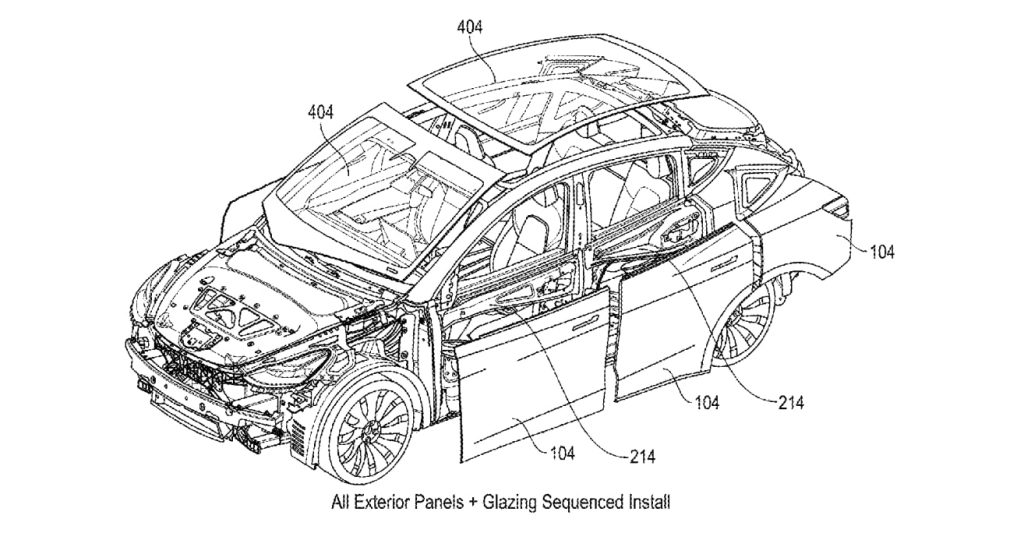

Tesla has been granted a brand new patent for its “Unboxed Course of” of producing, which goals to boost affordability for patrons by growing effectivity on the manufacturing stage.

That is a technique the corporate goals to create a bigger influence from begin to end, particularly with upcoming automobiles. For many who are usually not acquainted, the Unboxed Course of was first unveiled by Tesla again in 2023 throughout its “Investor Day.”

The corporate introduced forth the concept car manufacturing might shift from conventional meeting traces, making manufacturing extra environment friendly, cheaper, and extra scalable for the longer term, particularly with mass-market fashions like Cybercab.

The method consists of using previous strategies that Tesla has introduced into automotive manufacturing, together with Gigacasting and structural battery integration, with extra environment friendly “post-manufacturing” processes, like pre-painting.

Tesla describes the primary benefits within the patent:

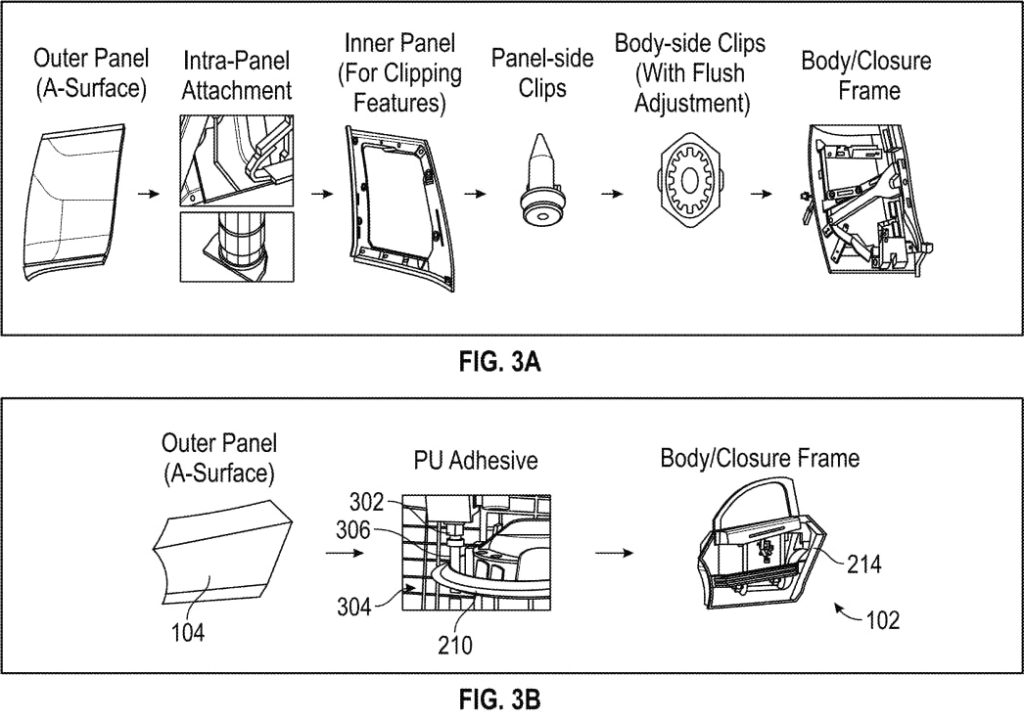

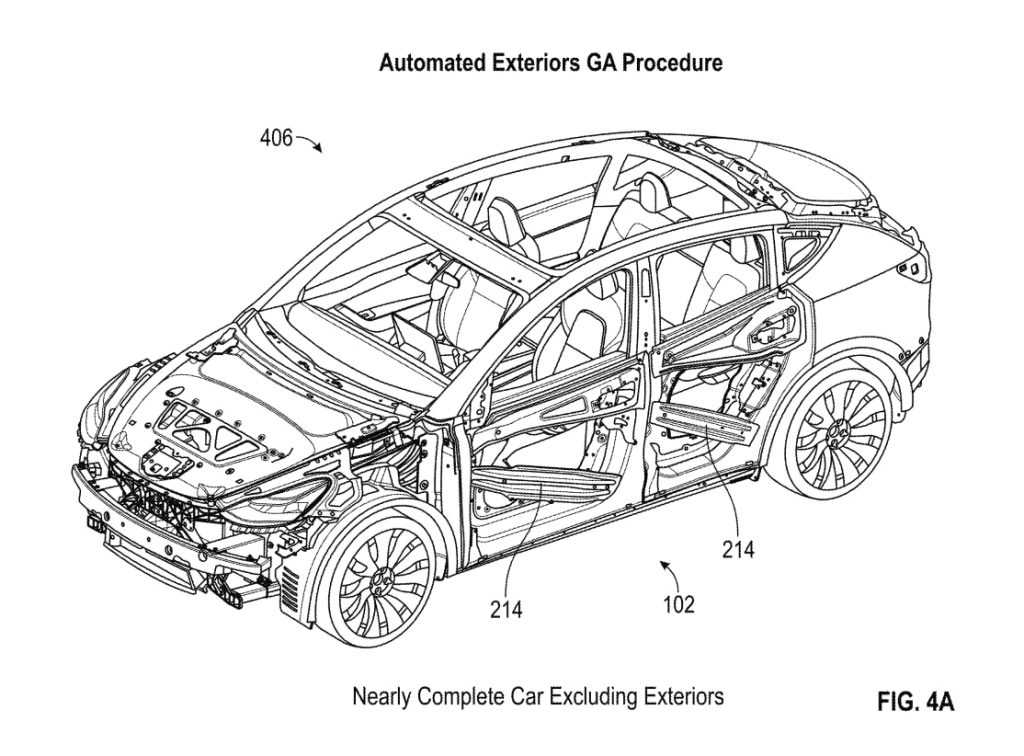

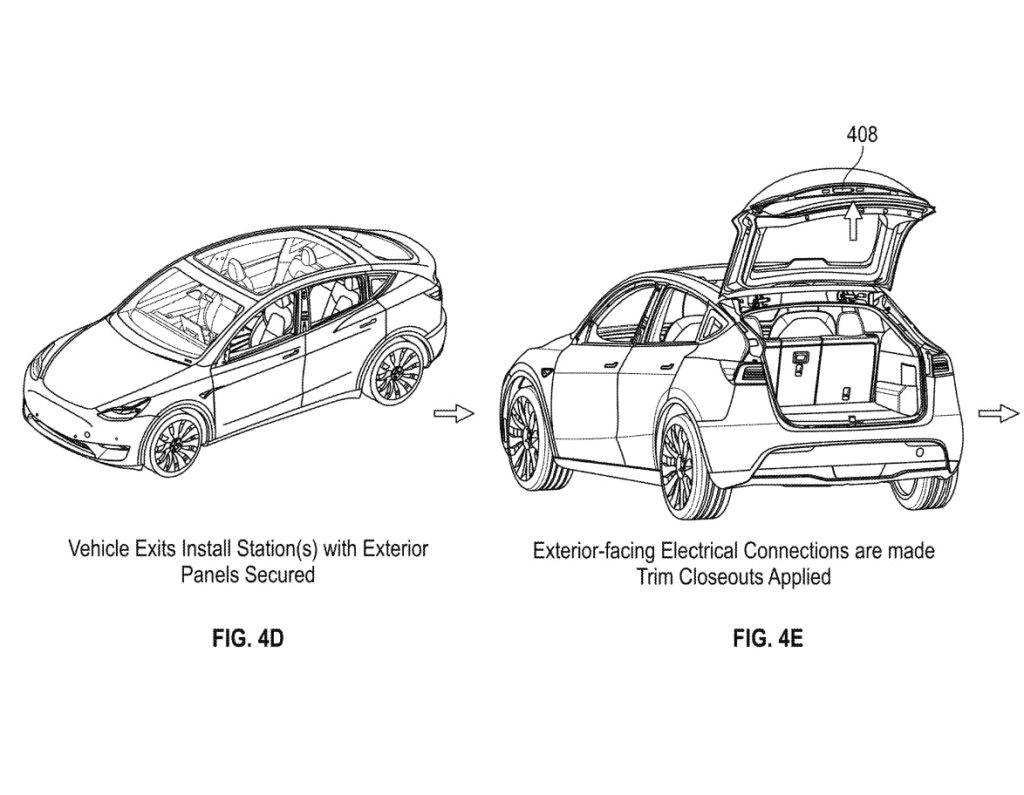

“The current disclosure pertains to an automatic system and technique for assembling exterior car elements to a car meeting construction. The system makes use of an automatic meeting cell with fixtures corresponding to every exterior car half and references a worldwide datum for exact alignment…The strategy improves meeting effectivity by compensating for substructure irregularities with an engineered adhesive hole and permits for continued meeting throughout adhesive curing by tacking operations.”

As a substitute of conventional welding methods, the corporate plans to make use of a distinct bonding technique, by adhesives.

The patent goes on:

“In described examples, a modular car structure permits for the meeting of a car in sections, that are then joined in a closing meeting operation. This strategy eliminates the standard want for welding stamped panels and making use of secondary coatings or portray on the full car meeting degree. As a substitute, the car might be constructed in elements, with steel floor remedies like e-coating and portray utilized beforehand.”

The aim behind this manufacturing course of is that Tesla will be capable of construct extra automobiles at a sooner charge for a lower cost, one thing it believes it might want to accomplish because it addresses autonomy and Robotaxis, that are in increased demand.

With this charge of velocity of producing, Tesla says conventional manufacturing strategies have the potential consequence of “compounding errors,” as “any slight misalignment or variance can add up.”

There’s a refined concentrate on effectivity, whereas additionally recognizing the significance of construct high quality. This could get rid of many of the points Tesla would confront with its present, extra conventional, linear manufacturing processes.