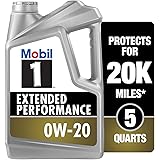

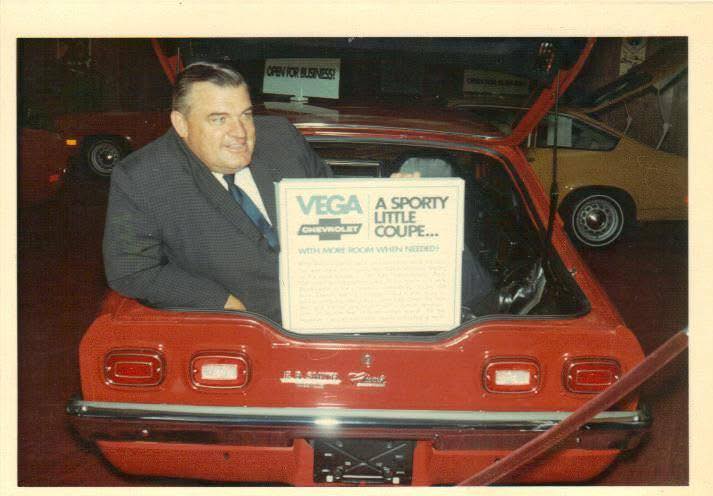

In 1971, Chevrolet unveiled a mind-bending solution to ship its new subcompact automotive: standing straight up on its nostril! Meet the Vert-A-Pac system, a wild engineering feat developed collectively by Common Motors and the Southern Pacific Railroad.

Conventional rail transport used open tri-level autoracks, cramming about 15 vehicles per 89-foot railcar—or as much as 18 for smaller fashions just like the Vega. However the Vega’s light-weight design left railcars underloaded by weight capability, driving up per-unit delivery prices. GM’s answer? Flip the script—actually.

The Vert-A-Pac railcar featured hinged facet doorways that swung all the way down to kind steep ramps. Staff drove Vegas nose-first up these inclines, then an enormous forklift-like loader pushed the doorways closed, securing 15 vehicles vertically on either side for a complete of 30 per railcar. This practically doubled capability in comparison with commonplace hundreds, slashing delivery bills by round 40% and enclosing the automobiles for higher safety towards climate and vandalism.

.jpg)

The vehicles had been specifically engineered for this: oil and fluids designed to not leak when vertical, and the physique structured to deal with the odd orientation with out injury. Loading regarded surreal—a forklift hoisting shiny crimson, blue, and inexperienced Vegas skyward like big toys being packed right into a freight automotive.

This revolutionary methodology was distinctive to the Vega and lasted solely by means of its manufacturing run (ending in 1977). Fashionable autoracks follow horizontal stacking, however the Vert-A-Pac stays one in all automotive historical past’s quirkiest logistics tales—a daring try to make an economic system automotive even cheaper to ship.